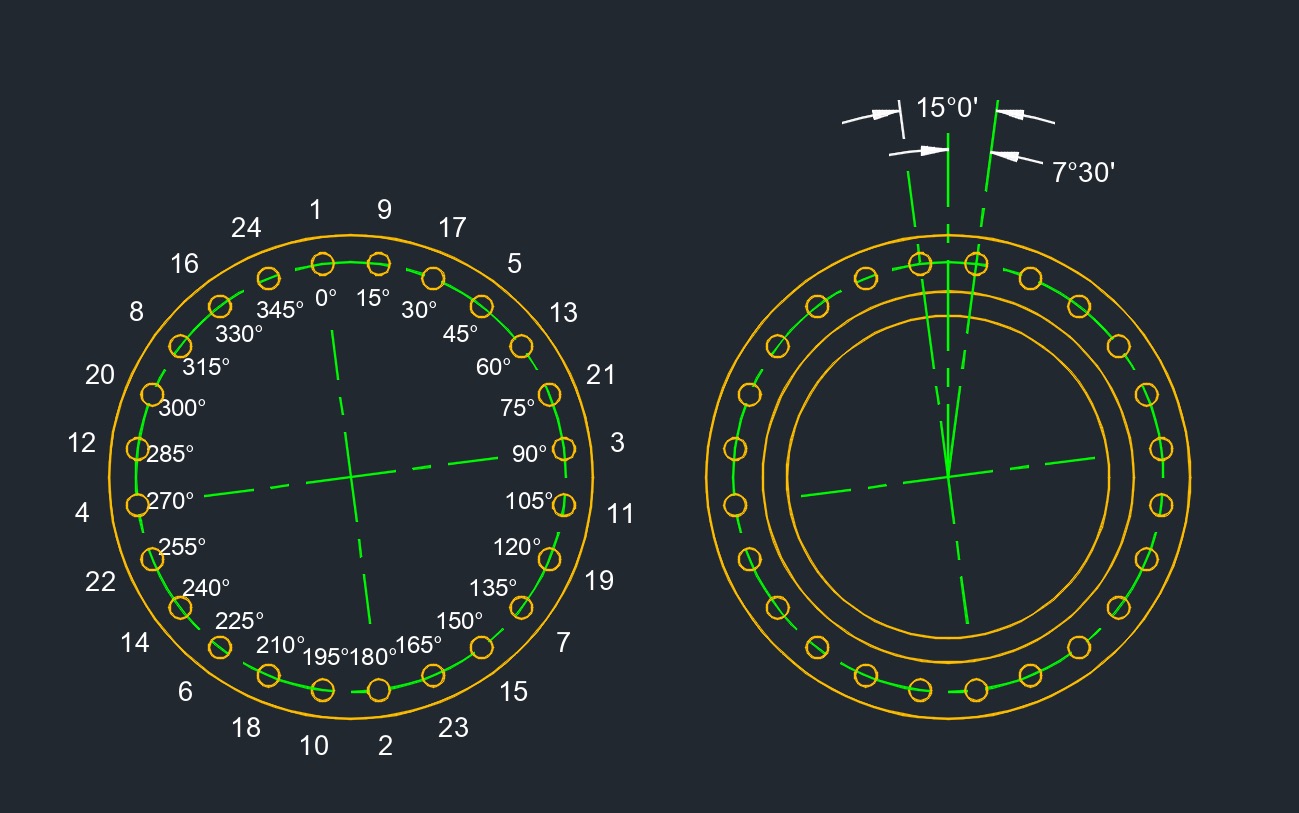

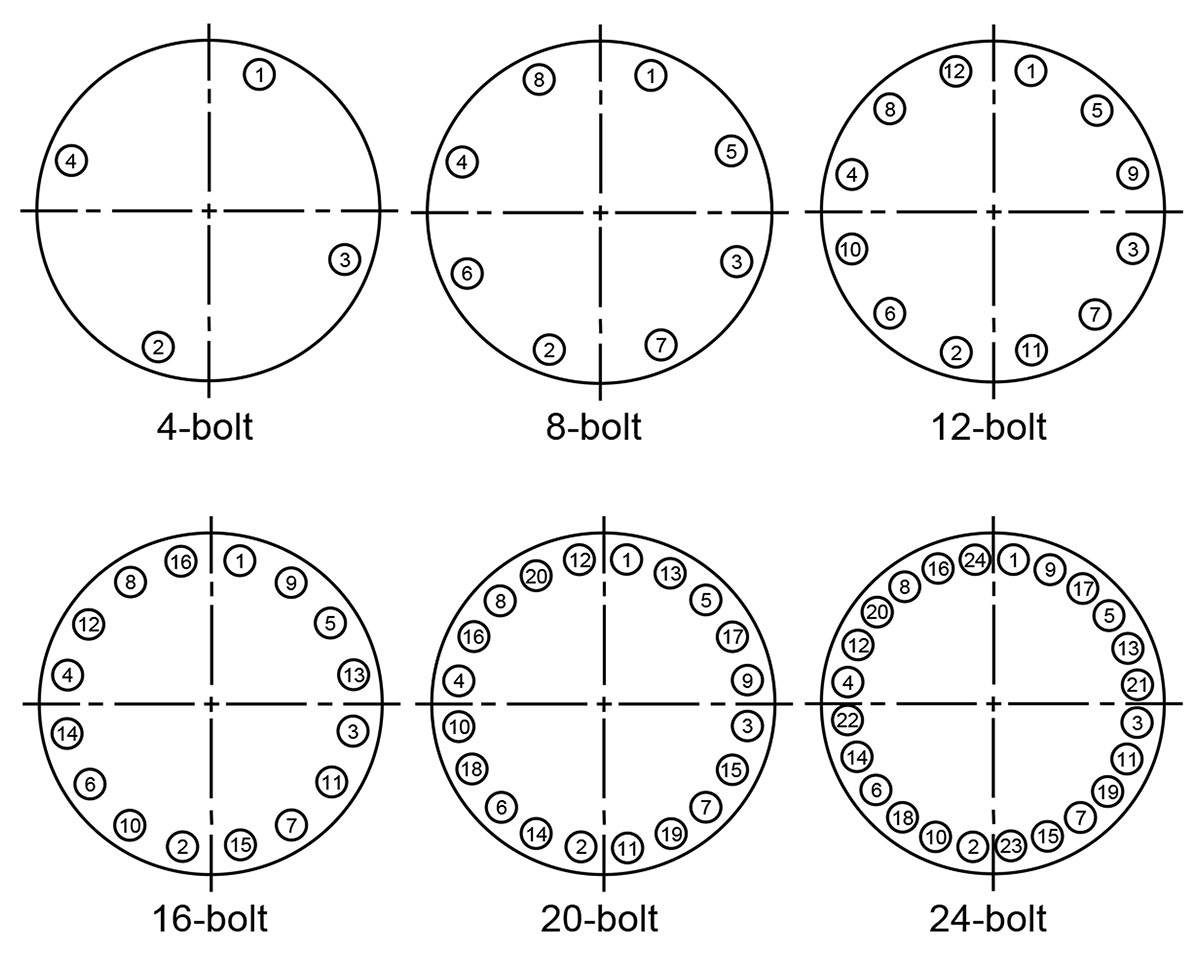

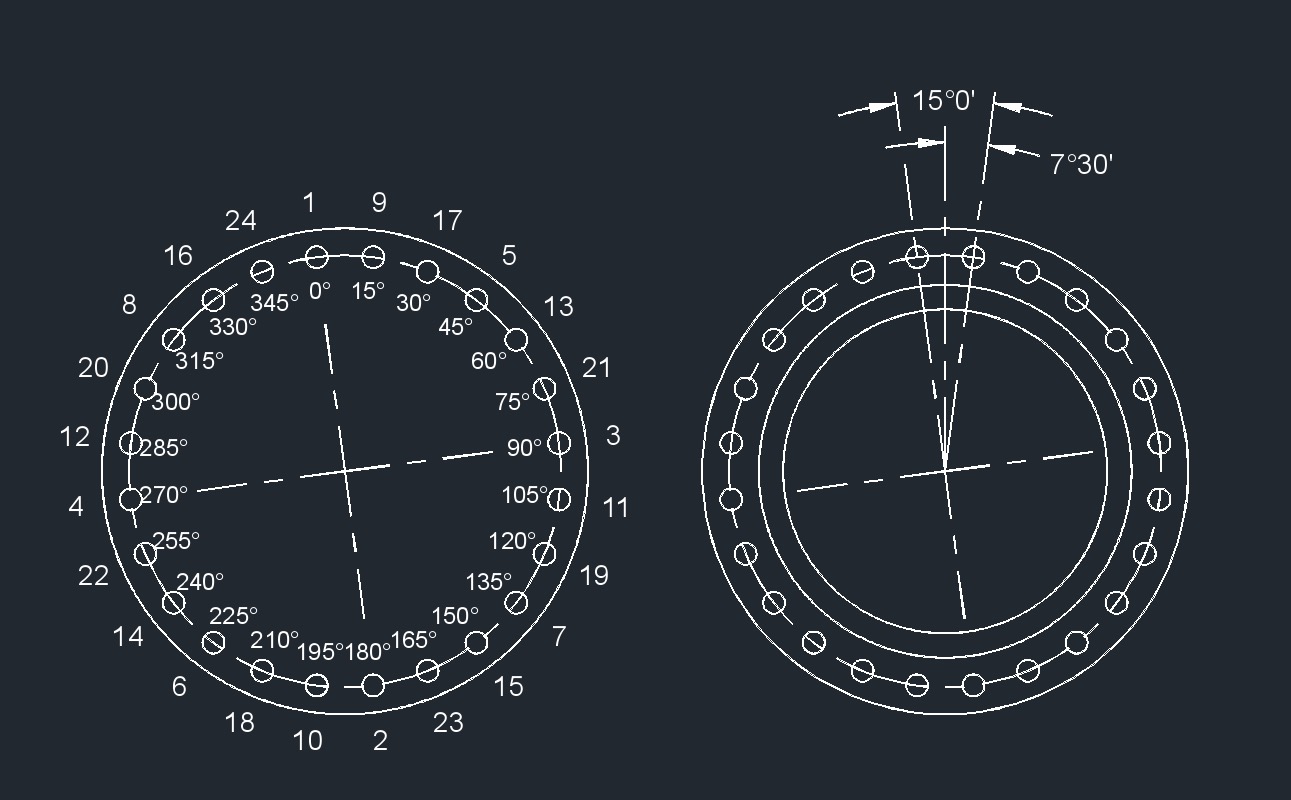

Torque Pattern For 24 Bolt Flange - Or they can be numbered by the order of tightening (fig 2 below). Web flange joints require proper tightening to avoid leakage. Web torque tables for the installation of flat gaskets with standard asme flanges. Research council on structural connections D = bolt diameter in mm. The nut factor or tightening factor (k) is a “modified” friction factor. In fact, there is no “silver bullet” bolt tightening sequence. Nut factor on flange bolt torque calculation. Web place the hubs on the engine and equipment shafts, then secure with set screws using the torque values listed in table 1. Flange bolt torque sequence for proper gasket installation.

Torque Table For Bolt Tightening 12 9 Elcho Table

Web flange joints require proper tightening to avoid leakage. Just enter the flange size, class, and type and the app instantly populates the correct values.

Flange Bolt Torque Sequence Chart A Visual Reference of Charts Chart

Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web in the metric system, torque applied, t = (k.d.f)/1000..

Torque Charts Industrial Bolting and Torque Tools

Apply the full rated torque to the flange bolts. D = bolt diameter in mm. Web control the torque applied, the bolting pattern and the.

Torque Sequence For 24 Bolt Flange New Images Bolt

Web torque tables for the installation of flat gaskets with standard asme flanges. Web apply minimal torque to take up any openings between the flanges..

Torque Sequence For 24 Bolt Flange New Images Bolt

Nut factor on flange bolt torque calculation. Web instant flange bolt sizes and torque patterns: Number the bolts/flange according to the bolt torque sequence. Web.

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange.

24 Bolt Torque Pattern

Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange.

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

Apply the full rated torque to the flange bolts. Web in the metric system, torque applied, t = (k.d.f)/1000. In fact, there is no “silver.

FlangeBoltingPatterns Industrial Bolting and Torque Tools

Web in the metric system, torque applied, t = (k.d.f)/1000. Nut factor on flange bolt torque calculation. Flanges according to asme b16.5 norm. East pompano.

Take The Torque To 1⁄2 The Recommended Level.

F = bolt load in n. Lookup flange bolt torque patterns on your phone in seconds. Web instant flange bolt sizes and torque patterns: Web rcsc’s specification for structural joints using astm a325 or a490 bolts (2000) is a widely used specification which discusses joints , fasteners , limit states , installation, and inspections.

Flange Bolt Torque Sequence For Proper Gasket Installation.

Uip supplies gaskets of all types & sizes for many industrial applications. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. In fact, there is no “silver bullet” bolt tightening sequence. Web apply minimal torque to take up any openings between the flanges.

East Pompano Beach, Fl 33060.

Nut factor on flange bolt torque calculation. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. Until all have been tightened. In this article, you will learn about the torque sequence of pipe flanges.

Apply The Full Rated Torque To The Flange Bolts.

Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Flanges in natural gas pipelines. Research council on structural connections Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks.