Sand Casting Pattern - Web sand casting steps. Excess sand is removed by a process known. The first step of sand casting involves the placement of the mold pattern in sand. The pattern is removed, leaving behind a perfect shape in the sand. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. The mold cavity is inspected for any defects or irregularities. The sand is packed around the pattern in a wooden or metal box called a flask. The first step in the sand casting process is to create the pattern. Incorporate the pattern and sand in a gating system. A pattern, which is a replica of the desired casting, is created in the.

Patterns and Cores Sand Casting. YouTube

Web the casting patterns are used to press into the sand mold to create the hollow cavity that allowing molten metal to be poured into.

Sand Casting

Web sand casting equipment within a foundry can be very basic or quite advanced, depending on the items being made. The sand is packed around.

Large Open Heart Sand Casting Pattern DIY Castings

The two halves of the mold are aligned and joined together. Web these patterns are used to create an impression in the sand mold. The.

Sand Casting Pattern at best price in Pune by Edgecon Technologies ID

Web what is the sand casting process? For that precision, we first have to make a pattern. Web these patterns are used to create an.

Sand Casting Services Austral Brass Foundry

Web below, you’ll learn more about the six primary steps of sand casting. Web pattern (casting) the top and bottom halves of a sand casting.

Types of Pattern in Sand Casting (3D Animation) YouTube

The number of castings and the required. Sand casting is an appropriate manufacturing process when the part to be produced is relatively large, has a.

The 6Step Process of Sand Casting Molding OneMonroe

Web sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a part to.

Sand Casting Patterns Forte Tool & Die

Submit the relevant part drawings, 3d files, and other information by clicking on the button below. These patterns are especially useful when the final product.

A 101 Guide to Sand Casting

The size and shape of the casting is directly influenced by the mold. Here, a split pattern is used. Sand casting is an appropriate manufacturing.

In Most Cases, The Replica Is Oversized So As To Create An Allowance For Shrinking.

This step involves creating a replica or duplicate of the object that will be cast. The number of castings and the required. Patterns (definition and concept of patterns, and types of patterns used in sand casting including solid pa. A sand casting pattern can be made up from any number of materials, ranging from wood to plastic to.

Web Sand Casting Steps.

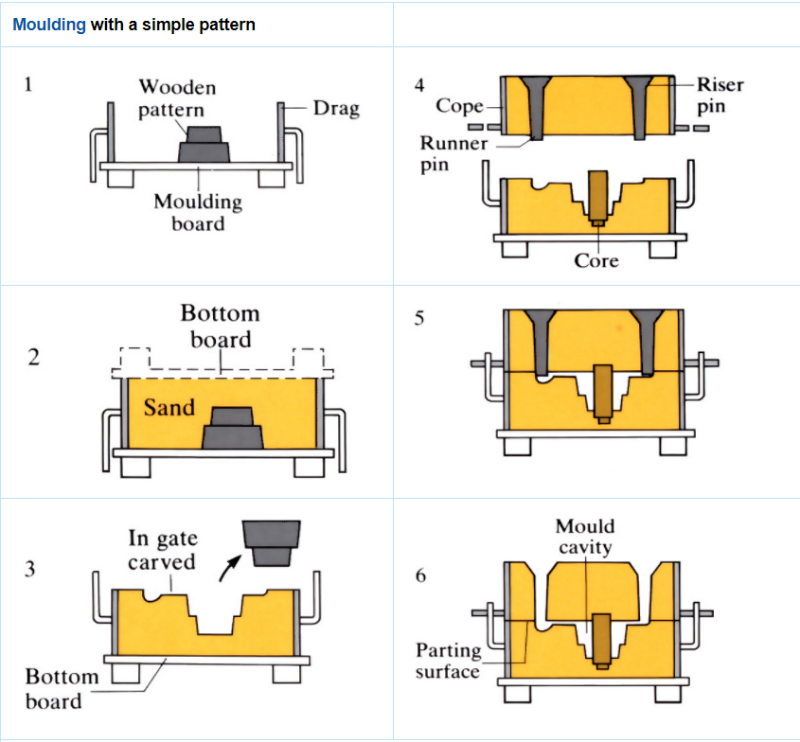

Web the sand casting process involves creating a mold using a pattern, pouring molten metal into the mold, cooling and solidifying the metal, and then removing the casting from the mold. The two halves of the split pattern nest together. The pattern is covered with parting compound and sand is rammed into the flask to form the drag. Excess sand is removed by a process known.

The Top Half Of The Mould Is Called The Cope.

After the shell mold has completely cured, the cast. Here, a split pattern is used. Incorporate the pattern and sand in a gating system. The mold cavity is inspected for any defects or irregularities.

The Process Begins With A Pattern.

These patterns are especially useful when the final product has complex geometries or undercuts that would be impossible to achieve with a solid pattern. In the sand casting foundry (whichever cast iron casting , aluminum casting or steel casting), a pattern set includes pattern, gating system feefer head, riser and pattern plate. Web the pattern material is chosen based on the casting volume and process used. The split pattern shown with cutaway of flask.