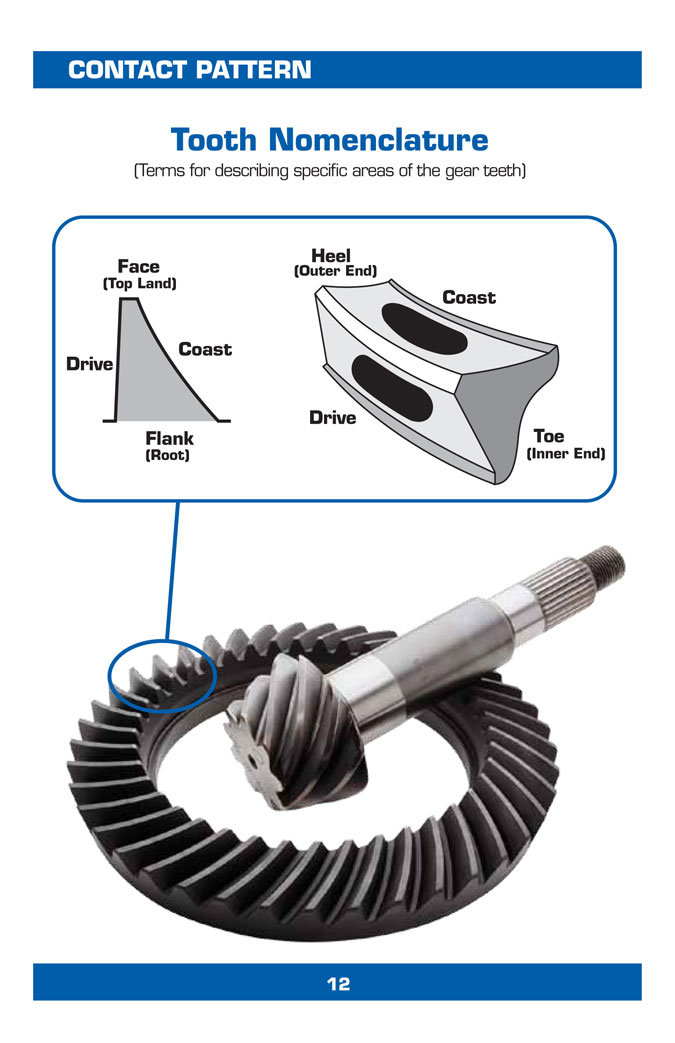

Ring And Pinion Gear Patterns - Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. Ensuring peak performance and longevity. The top land of a. Web see how to set up a ring and pinion gear set. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Drive pattern (convex side of gear) moves slightly lower and toward the toe. I am setting up a gm 12 bolt truck rear with richmond 3:73 gears. Web ring and pinion pattern question. Ring gear tooth profile face hobbing face milling the toe of the gear is the portion of the tooth surface at the end towards the center. Make large pinion depth adjustments first.

How to identify your ring and pinion Pro Gear and Transmission

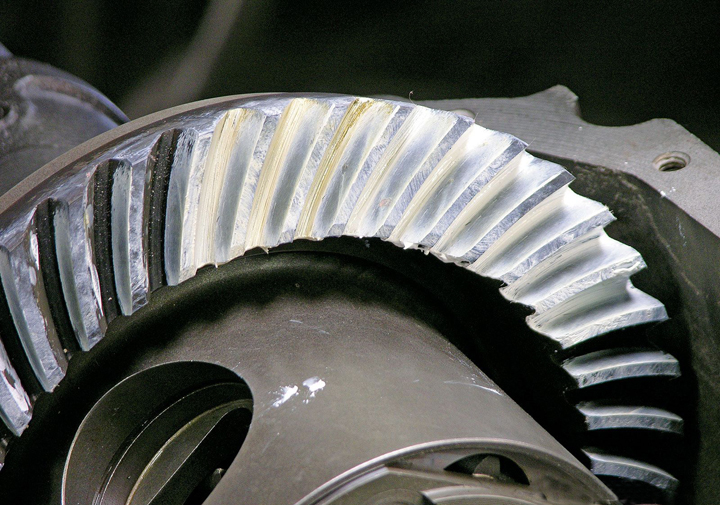

Use shims to move the ring gear farther from the pinion gear to increase backlash. Apply tooth contact compound to the ring gear in two.

Ring & Pinion Installation Instructions The Ranger Station

Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. Yukon provides.

How To Create & Read Ring Gear Patterns

This video was created to give people a basic understanding of. Web ring and pinion pattern question. Web use shims to move the ring gear.

Dana 44 Ring & Pinion Setup, Pattern / Ring Problems? YouTube

Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting.

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Ensuring peak performance and longevity. Web ring and pinion pattern question. (2) increasing backlash moves the ring gear away from the pinion. Web here's how.

How to Set up Your Rear Gear Correctly RacingJunk News

Web doing my first rear gear change and need some opinions on my ring pattern. If your gear tooth pattern is too low, down towards.

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Web the final pinion position will be verified by using the gear contact pattern method described as follows: Use shims to move the ring gear.

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Learn more about ring gear patterns in our “how the create & read ring gear patterns” article. Rotate the pinion to turn the ring gear.

How to Set up Your Rear Gear Correctly RacingJunk News

I run the pattern and it seems a little high on the face of the drive side. This will help give you a nice clear.

Web See How To Set Up A Ring And Pinion Gear Set.

I have the pinion depth set at 2.8235 and the backlash at.0095 (gear specs are 2.823 on the depth and.010 on the bl). Coast pattern (concave side of gear) moves lower and toward the toe. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear.

Web Reading And Interpreting Gear Patterns Can Be Very Confusing If They Aren't Obvious Patterns.

Ensuring peak performance and longevity. Use shims to move the ring gear closer to the pinion gear to decrease backlash. Web doing my first rear gear change and need some opinions on my ring pattern. Learn more about ring gear patterns in our “how the create & read ring gear patterns” article.

I Run The Pattern And It Seems A Little High On The Face Of The Drive Side.

I have been fighting this for a couple of weeks now. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. The pattern on the drive side is most important to read on rear axles, but if a standard cui ring gear is used up. If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion.

The Coast Side Contact Pattern Will Also Move Down Towards The Flank But Out Slightly Towards The Heel Of The Ring Gear.

As for the other hardware: Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Web (1) decreasing backlash moves the ring gear closer to the pinion. Supply some drag on the ring gear while doing it.