Ring And Pinion Gear Pattern Chart - If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion. Shallow pinion position, with correct backlash, moves the pinion further from the ring gear. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web gm 8.5 gear pattern. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. Pinion resistance against the rotating ring gear helps establish a good pattern. Dialing in the tolerance between the gears will ensure a smooth. Web front axles, so use the drive side for reading the pattern. Coast pattern (concave side of gear) moves lower and toward the toe. Web this will move the drive side contact point down towards the gear flank (root) and slightly in towards the toe.

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

I have included two charts here to help you understand and adjust the pattern and backlash. This will help give you a nice clear pattern.

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

(2) increasing backlash moves the ring gear away from the pinion. Web front axles, so use the drive side for reading the pattern. Web the.

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Coast pattern moves deeper on the tooth and toward the heel. There should usually be some clearance between the pattern and the top of the.

Ring Gear Contact Pattern

Web this will move the drive side contact point down towards the gear flank (root) and slightly in towards the toe. Web (1) decreasing backlash.

How to Set up Your Rear Gear Correctly RacingJunk News

Ensuring peak performance and longevity. Rotate by grabbing and turning the ring gear, not the pinion. If your gear tooth pattern is too low, down.

Ring And Pinion Patterns Explained

The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Drive pattern moves slightly higher and toward the heel. Carefully apply moderate.

Ring and Pinion Gear Ratio Calculation Chart Quadratec

The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. Web gm 8.5.

How To Create & Read Ring Gear Patterns

(2) increasing backlash moves the ring gear away from the pinion. Web front axles, so use the drive side for reading the pattern. Drive pattern.

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

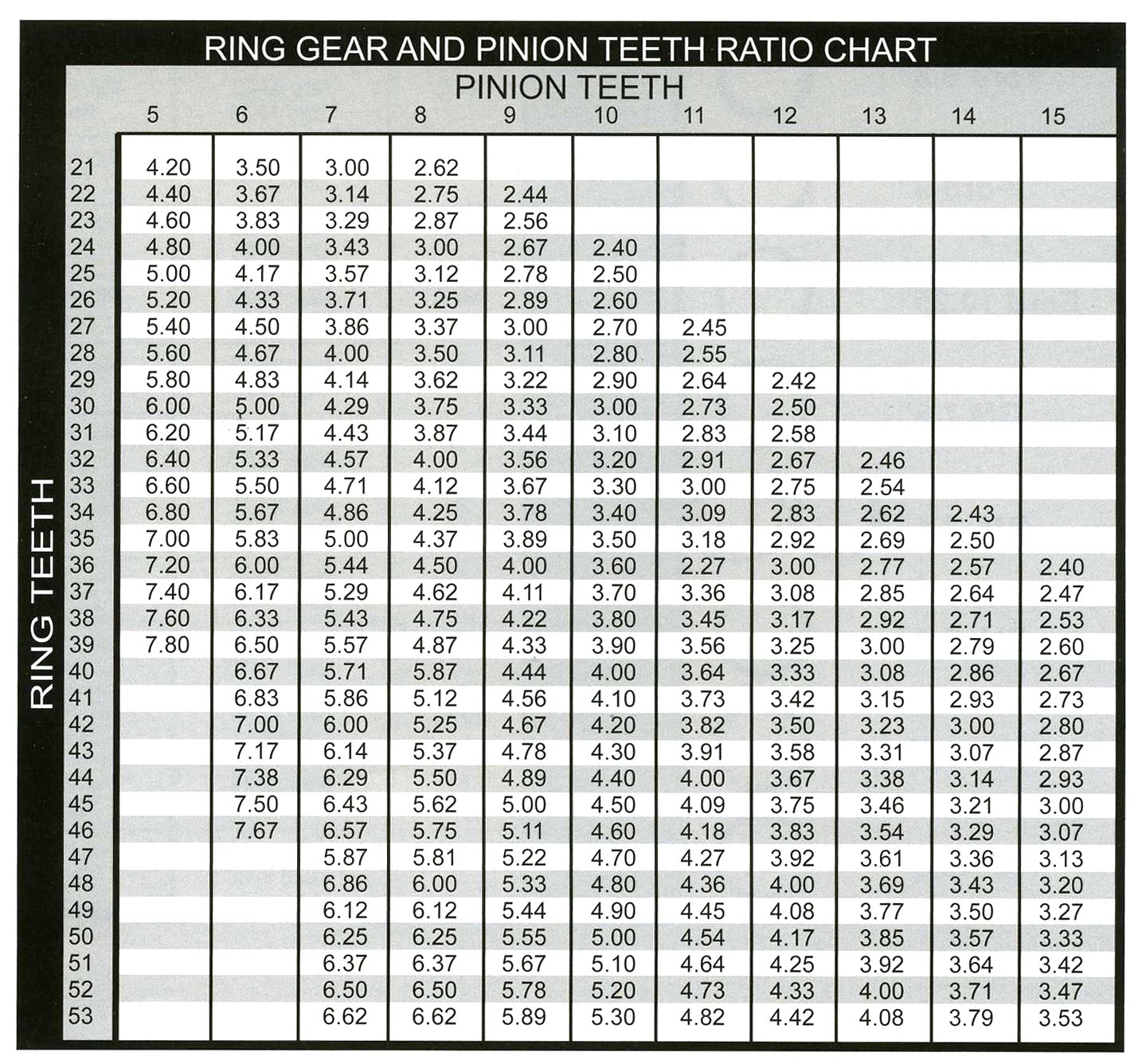

The ratio is the number of teeth on the ring gear divided by the number of teeth on the pinion gear. Supply some drag on.

Rotate By Grabbing And Turning The Ring Gear, Not The Pinion.

The pattern on the drive side is most important to. I am now in the process of setting up the gear pattern and shimming the pinion/carrier. Web the pattern refers to how the ring gear and pinion gears mesh. Rotate the ring gear several times by hand and inspect the ring gear teeth.

The Mating Ring Gear Is Bolted To The Differential Carrier And Spins On A Set Of.

Rotate the pinion to turn the ring gear four complete revolutions on the drive side and then four in the opposite direction for the coast. If the pattern is heavy on I have a setup pinion bearing so it is easy for me to pull it apart and change shims. Rotate by grabbing and turning the ring gear, not the pinion.

Dialing In The Tolerance Between The Gears Will Ensure A Smooth.

Ensuring peak performance and longevity. Two cut ring & pinion gears (face hobbed): So, if the ring gear has 41 teeth and the pinion has 11 teeth, the ratio is 3.73:1 (41 divided by 11). Web front axles, so use the drive side for reading the pattern.

Use Something Soft, Like A Small Block Of Wood.

This video was created to give people a basic understanding of. Drive patternmoves deeper on the tooth (flank contact) and slightly toward the toe. Web this will move the drive side contact point down towards the gear flank (root) and slightly in towards the toe. Toyota gear installs arizona by zuk.