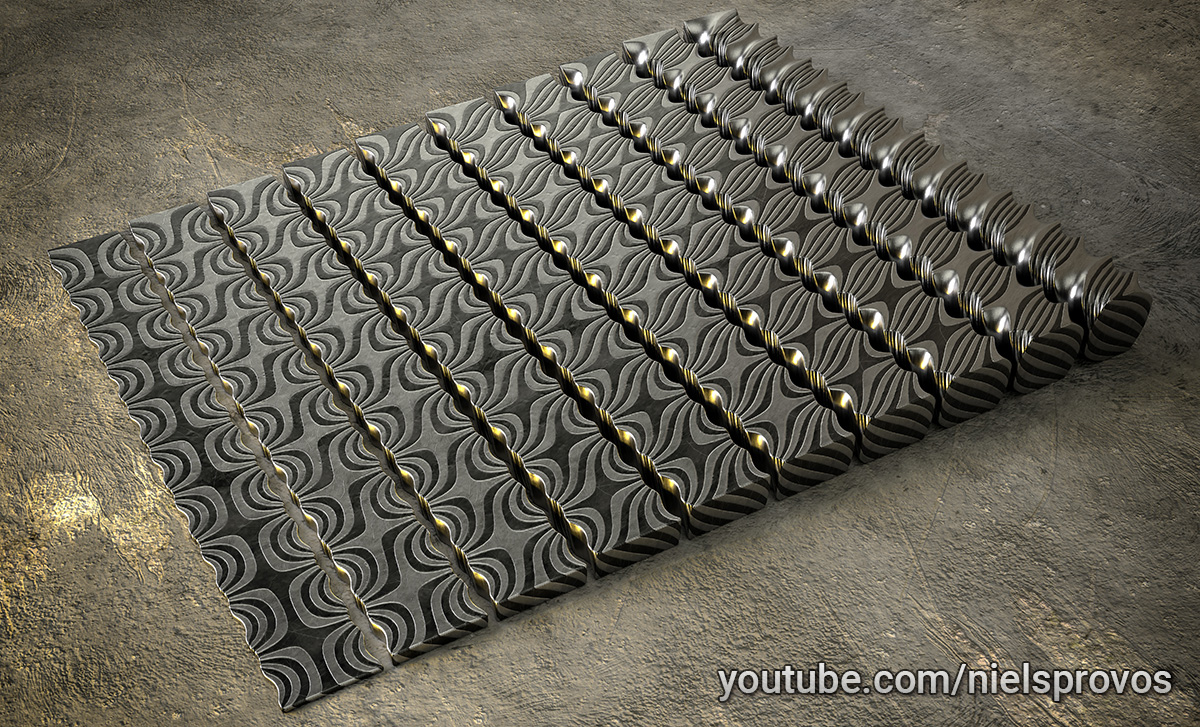

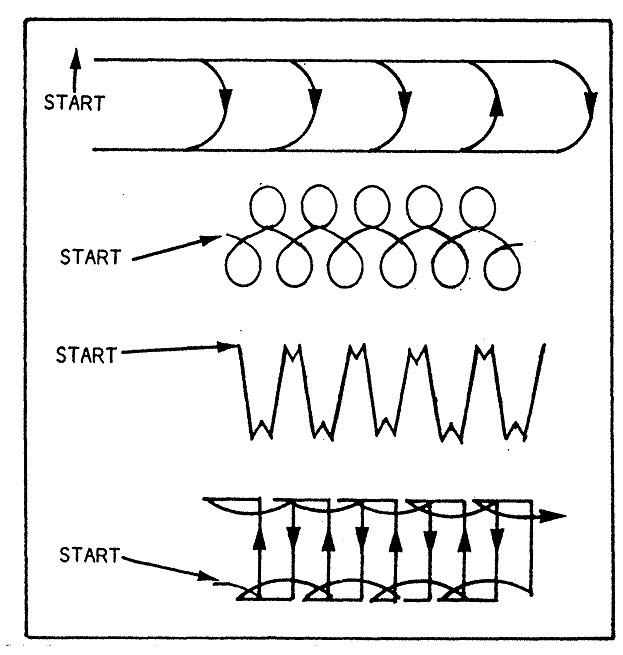

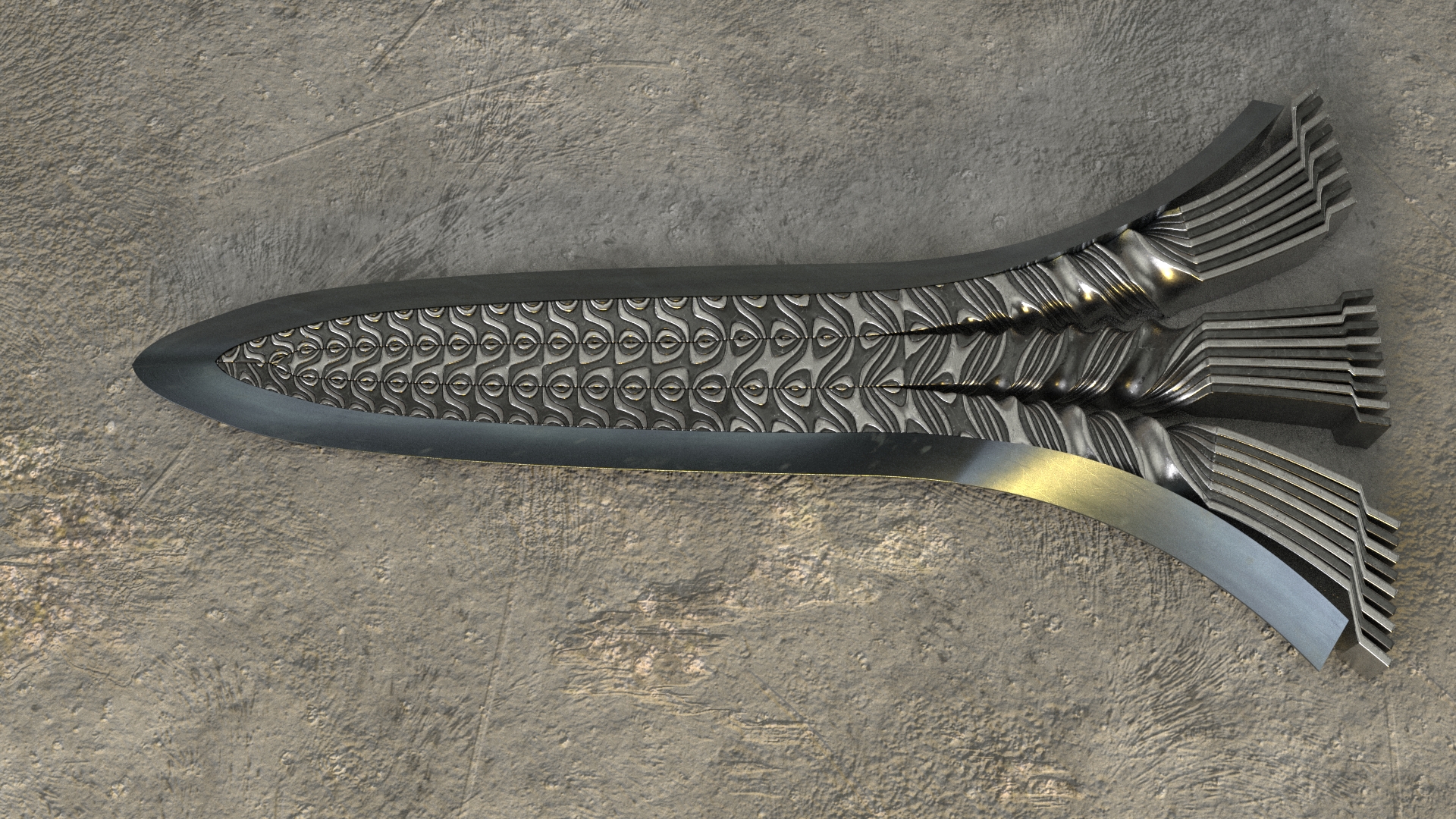

Pattern Welding - It's used when you make two or more welds on the same seam. Unleash the beauty of metal with pattern welding! This pattern is particularly useful for welding fillet joints and corner joints. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated. You will make a weaving pattern in order to cover a larger area. Find out how and compare it with the original damascus steel in this article. You use this motion to make cover welds over stringer beads (multipass welding). Web pattern welding refers to the unique process of forging knives and swords by using metals of differing compositions and then twisting them to create a characteristic wavy pattern. These patterns form partly because sufficiently differing metals that intersect the surface reflect lights differently.

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Web the term pattern welding refers to the process of forging a sword or blade using multiple pieces of metal with differing composition, twisting them.

Weaving in welding A comprehensive guide to weave patterns

This pattern is particularly useful for welding fillet joints and corner joints. Web posted on september 2, 2010 by dekerseptember 2, 2010. The eye catching.

Pattern Welding Explained

37k views 15 years ago. You use this motion to make cover welds over stringer beads (multipass welding). Here is something easy that will get.

Everything about Pattern Welding Steel

When making a knife a high or medium carbon steel is needed. This technique has been used for centuries to create a wide range of.

Pattern welding patterns; overview... An excellent overview ot the

Web pattern welding explained. Unleash the beauty of metal with pattern welding! It is not however, any form of magic. Web pattern welding, also known.

Welding Techniques

Part 1 (introduction to the purpose of pattern. So, i think i’m going to try and begin work on a section.continue reading →. This is.

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Web posted on september 2, 2010 by dekerseptember 2, 2010. When somebody who is familiar with pattern welding, whether it be in. Pattern welding is.

Pattern Welding Explained

Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated. When.

Pattern Welding Explained

Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated. 47k.

These Metals Are Then Forge Welded And Twisted To Form A Pattern That Is Visible On The Blade.

This instructible assumes a working knowledge of pattern welding. Unleash the beauty of metal with pattern welding! This pattern is particularly useful for welding fillet joints and corner joints. 4 x black square section spring washers.

When Somebody Who Is Familiar With Pattern Welding, Whether It Be In.

These patterns form partly because sufficiently differing metals that intersect the surface reflect lights differently. I’m often asked where the patterns in my steel come from. In other words you use this when you are layering welds. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern.

Here Is Something Easy That Will Get You Started And Boost Your Confidence.

Find out how and compare it with the original damascus steel in this article. Web pattern welding refers to the unique process of forging knives and swords by using metals of differing compositions and then twisting them to create a characteristic wavy pattern. When performing circular welds, it’s essential to maintain a consistent speed and maintain a steady arc length to achieve a uniform bead. Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated.

This Process Of Joining Many Layers Of Metal Is Also Known As.

Dealing with medium and high carbon steels. So, i think i’m going to try and begin work on a section.continue reading →. 37k views 15 years ago. When making a knife a high or medium carbon steel is needed.