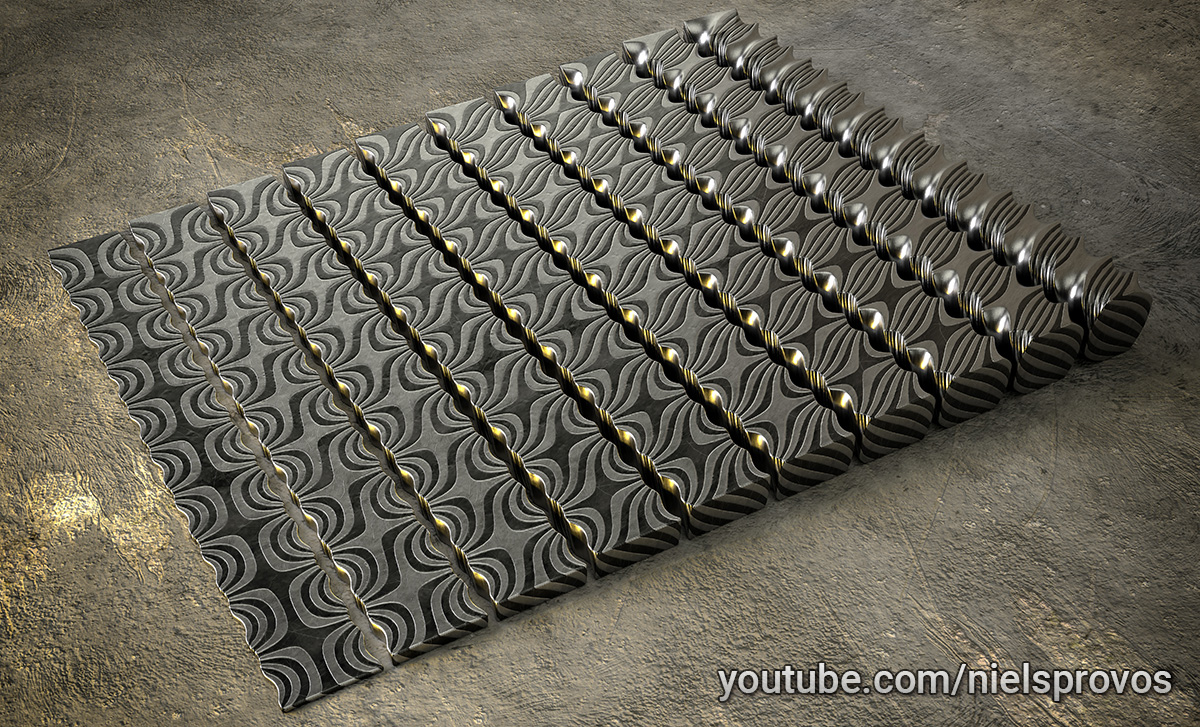

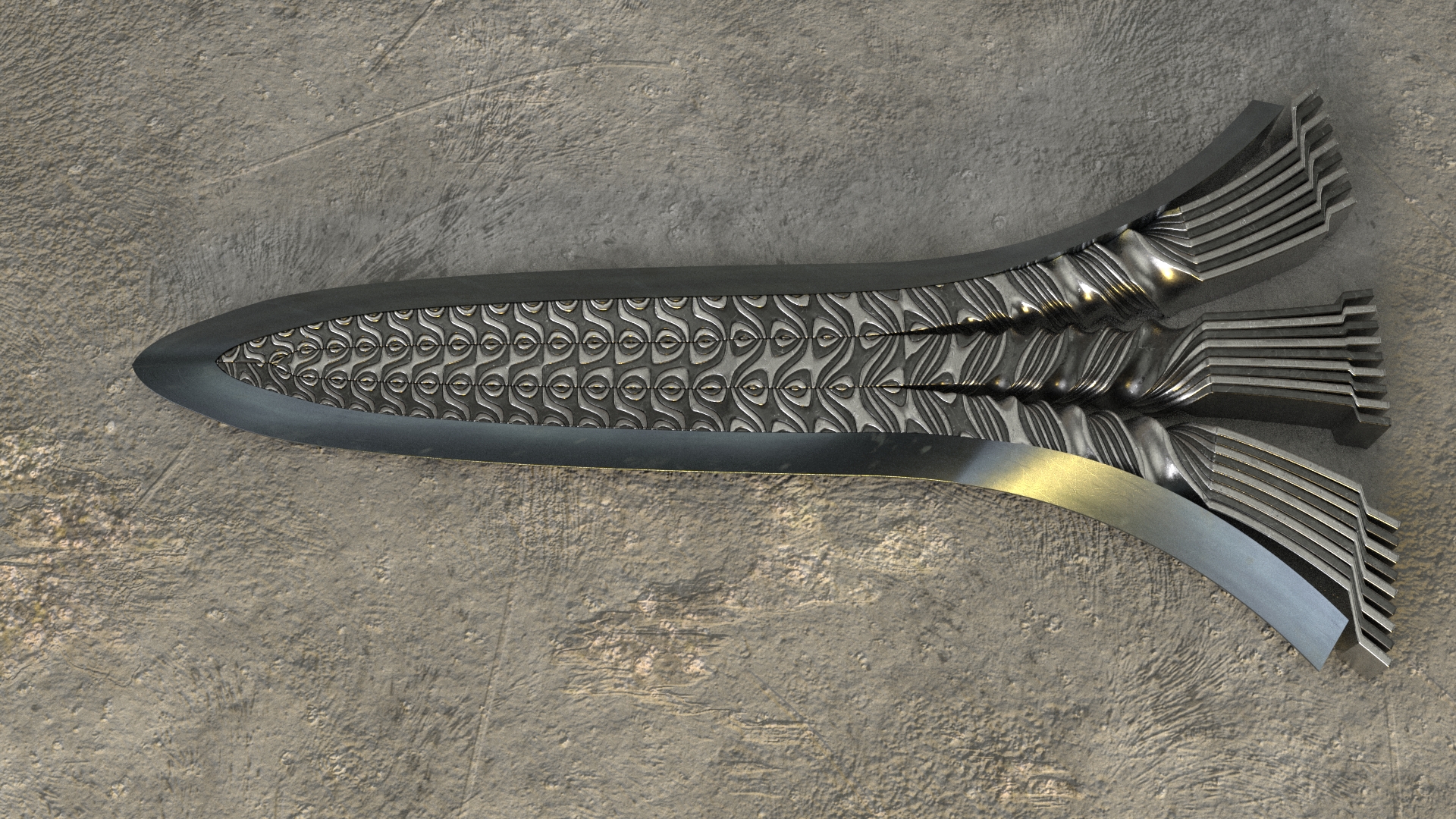

Pattern Welded - Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipu. I’m often asked where the patterns in my steel come from. The esthetic result is similar: Web pattern welding is the process of mixing different steels by forging. Web pattern welding offers a middle way out of the dichotomy between rigorous development of detail and warmth and vitality of the object. Despite this difference, current codes often generalize the findings from cms members to hss members, and the previous unified residual stress models are generally. Many but not all seaxs are pattern welded and the complexity of the patterning vary s greatly with region, time and presumably with the wealth of the original owner. Web pattern welded steel covering the soft iron core had a similar purpose to the san mai knives of the japanese. However, rust and other oxidation forms make it challenging to notice the. The technique is an extensive process that creates a strong, hard, and flexible steel.

Everything about Pattern Welding Steel

You will also need to clean the washers to remove the fire scale. The iron or steel used must be contrasting so that they are.

How Pattern Welded Steel is Made Explained by Blacksmiths (Part 2 of

Bind with the tie wire in alternate layers the two brite steel nails, and three black washers. Web pattern welding is an amazing and amazingly.

Weaving in welding A comprehensive guide to weave patterns

Bind with the tie wire in alternate layers the two brite steel nails, and three black washers. Web forge welding is second only to material.

Pattern Welding Explained

Web forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Despite this difference, current codes often.

Help me understand pattern welding. Beginners Place Bladesmith's

Web part 1 (introduction to the purpose of pattern welding): The technique is an extensive process that creates a strong, hard, and flexible steel. These.

a pattern welded Viking sword part 1. YouTube

Forge welding differs from more more modern welding techniques such as smaw (shielded metal arc welding, commonly called “stick” welding), fcaw (flux core arc welding,.

welding art projects for beginners Weldingart Welding art, Welding

Unlike wootz steel, whose pattern arises from the presence of one or more impurities, pattern welded steel is the deliberate combination of billets made from.

Pattern Welding Explained

The technique is an extensive process that creates a strong, hard, and flexible steel. Web the process of pattern welding. Although modern steelmaking processes negate.

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Web step by step guide to forging damascus (pattern welded) steel in a propane forge by hand for beginners. Web pattern welding was an outgrowth.

You Will Also Need To Clean The Washers To Remove The Fire Scale.

Web pattern welding was an outgrowth of laminated or piled steel, a similar technique used to combine steels of different carbon contents, providing a desired mix of hardness and toughness. Many but not all seaxs are pattern welded and the complexity of the patterning vary s greatly with region, time and presumably with the wealth of the original owner. Moran displayed his knives at the knifemakers’ guild show. Virtually all existing swords from these times are in excavated condition and in many cases weak acidity in the earth or water.

Web Part 1 (Introduction To The Purpose Of Pattern Welding):

Keep one washer in reserve, this will be the cutting edge. Heat up all the spring steel washers in the forge, and straighten them. This technique has been used for centuries to create a wide range of objects, including swords, knives, and other decorative items. Web pattern welded steel covering the soft iron core had a similar purpose to the san mai knives of the japanese.

The Technique Is An Extensive Process That Creates A Strong, Hard, And Flexible Steel.

Unlike wootz steel, whose pattern arises from the presence of one or more impurities, pattern welded steel is the deliberate combination of billets made from different metals (iron alloys) during the making of a blade. When somebody who is familiar with pattern welding, whether it be in. Web pattern welding, developed for laminated or laminated steel, is a comparable method for the fusion of steels with different levels of carbon to obtain the desired combination of toughness and hardness. Web pattern welding is a process used to forge and create a composite steel material with distinctive patterns.

These Are The Most Basic Damascus Patterns And The Same Patterning Techniques, And Several Others, Are Employed For More Advanced Patterns.

Before moving on to more advanced patterns and techniques, the damascus steel maker should become adept at the forge. Web the seax can vary greatly in form , from a small 5” long scramaseax used for every day tasks, to the 24”+. Forge welding differs from more more modern welding techniques such as smaw (shielded metal arc welding, commonly called “stick” welding), fcaw (flux core arc welding, commonly seen in gas. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material.