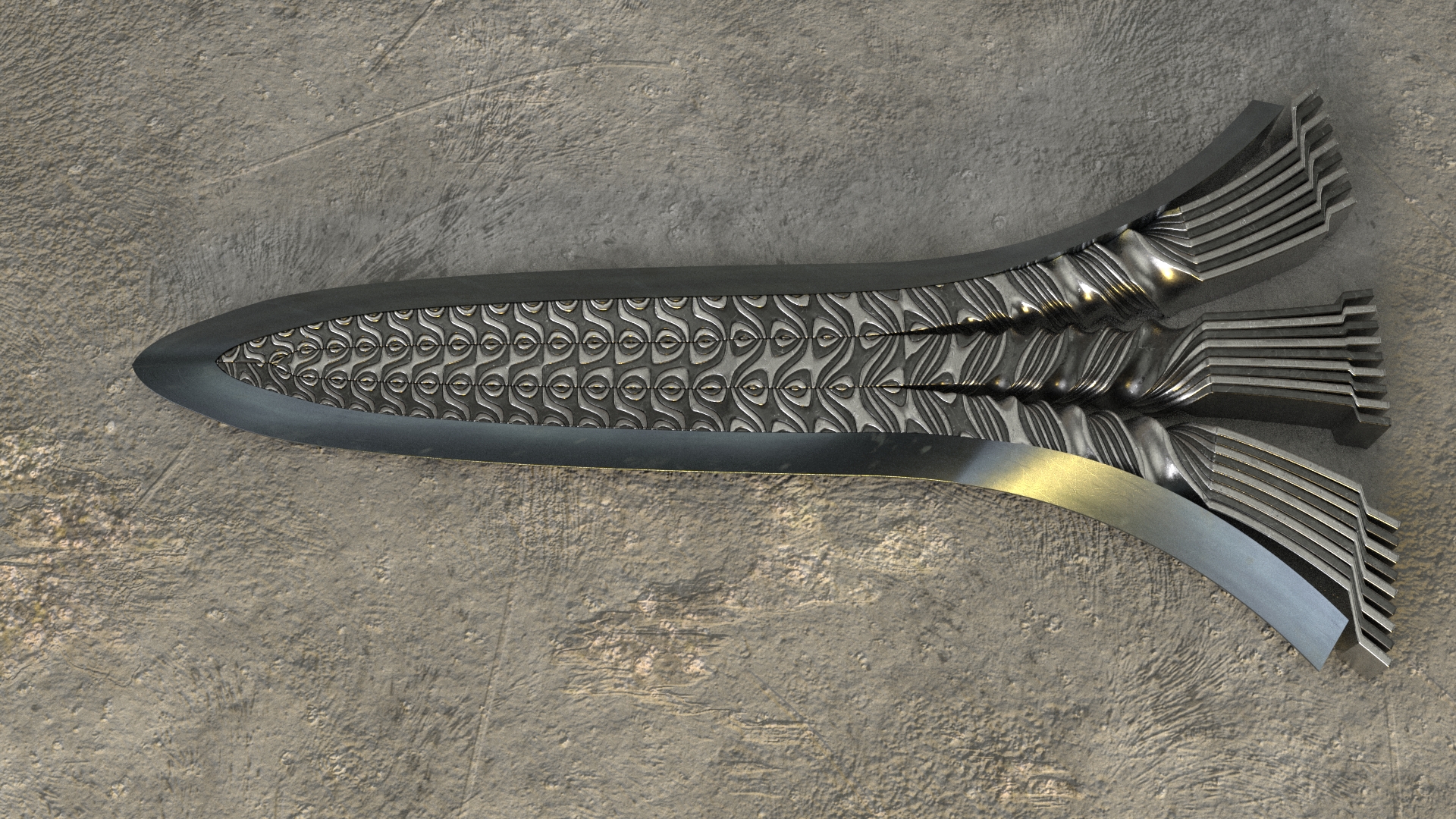

Pattern Welded Sword - Web pattern welded swords show a distinct interwoven figuring in the steel that imparted an especial beauty and visual liveliness to the blade. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipu. Virtually all existing swords from these times are in excavated condition and in many cases weak acidity in the earth or water. Later viking swords, either locally produced or bought, were made by pattern welding, a sophisticated technique in which numerous thin strips of metal are interwoven together at high heat to create a stronger blade.the trick to creating an ideal sword. That's why there are a lot of modules around those finds. When struck at high heat, steel will form a molecular bond and fuse together. Discussing pattern welded swords means to look at a. Far be it from me to doubt pleiner's analysis of this sword. Web damascus steel viking sword (about):

a pattern welded sword part 4, making the handle. YouTube

Pattern welding has a rich history dating back. Twisting, heating, and hammering drives the crystalline structure of the steel to form the wavy, watery pattern.

a pattern welded sword, the complete movie. YouTube

The need for these techniques come from the competing requirements of a good sword: Once the billet is welded, i draw it out using the.

Pattern Welded Viking Sword Damascus Full Tang eBay

The blades, pommels and guards are entirely made of damascus steel, culminating into a stunning masterpiece which will impress even the most discriminating. Pattern welding.

TherionArms Godfred patternwelded viking sword

Pattern welding diminishes during the middle of. Two or more metals of different combinations are heated to a very high temperature and then hammered together..

Large Pictures 1

95.9 cm (37 3/4 in) x 11 cm (4 5/16 in). That's why there are a lot of modules around those finds. Web a close.

silverinlayed/patternwelded sword from a museum in Busdorf

Web pattern welded steel is made using a similar technique to laminating or piled steel. The blade construction is made of three billets of laminated.

Pattern Welding Explained

Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. Web pattern welding, also.

Formidable King Pattern Welded Damascus Steel Viking Sword

Pattern welding diminishes during the middle of. Far be it from me to doubt pleiner's analysis of this sword. It is comprised of two twisted.

Direct Octagonal Profile Pattern Welded Calabash Sword

This is a picture of the initial forge welding of the edge billet which has twelve layers of alternating 1084 and l6 steel. Web we.

The Iron Or Steel Used Must Be Contrasting So That They Are Optically Different And Should Be Visible At The Surface Of The Sword.

When struck at high heat, steel will form a molecular bond and fuse together. Pattern welding diminishes during the middle of. Folded steel, inlaid runes, carved bronze and bone and a viking pattern welding demonstration.owen bush, ama. The other, incomplete, sword, was even better.

Far Be It From Me To Doubt Pleiner's Analysis Of This Sword.

The blade construction is made of three billets of laminated steel. Twisting, heating, and hammering drives the crystalline structure of the steel to form the wavy, watery pattern which the technique produces. 12 in the picture accessed by this link) produced a complex pattern welded sword that looks suspiciously like one of the the more complex pattern welded swords made about 600 years later. Once the billet is welded, i draw it out using the hydrolic press and.

It Is Comprised Of Two Twisted Bundles Forged Flat With A Wrought Iron Back And A Carbon.

Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipu. Later viking swords, either locally produced or bought, were made by pattern welding, a sophisticated technique in which numerous thin strips of metal are interwoven together at high heat to create a stronger blade.the trick to creating an ideal sword. The blades, pommels and guards are entirely made of damascus steel, culminating into a stunning masterpiece which will impress even the most discriminating. This style of pattern weld could possibly be the blodida pattern or blood eddy described in the norse sagas.

It Must Be Hard And Durable (Hold A Keen Edge) Yet Must Also Be.

Pattern welding has a rich history dating back. Viking swords average about 37 inches in length overall and will, especially toward the later part of the period, show increasing taper towards the point and a deeper central fuller in the center of each blade face. Web at least one celtic smith making a la tène sword around 300 bc (no. Web a 10th century ce steel sword, likely made in scandinavia.