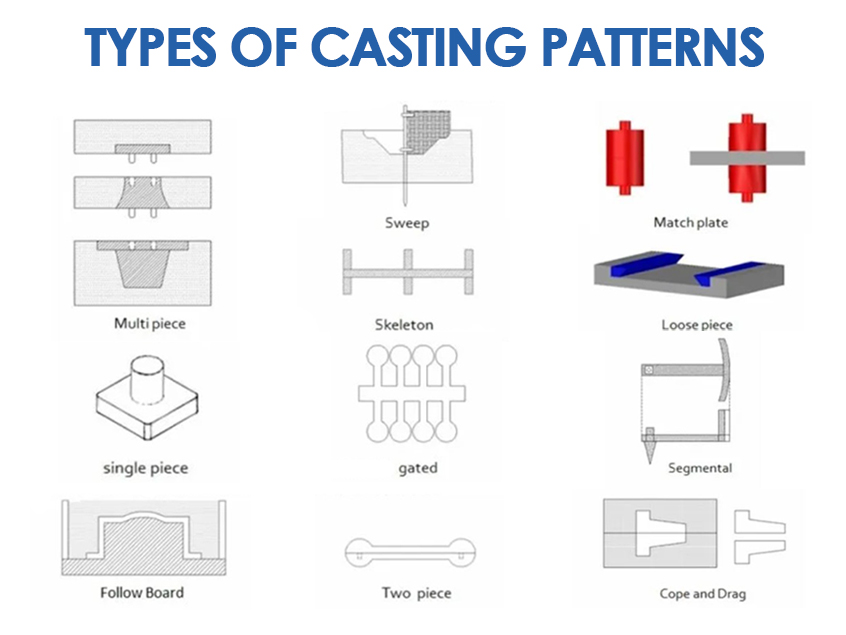

Pattern Casting - Web sweep pattern is suitable when the casting is large and symmetrical about the axis (e.g., bells). The final shape of products was decided by the mold cavity, while the shape of the mold should be. Reusable: types of pattern in sand casting or plaster. Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. Easier to perform than other types of casting processes. From this mold, a pattern is cast from a material that can melt or. In casting, a pattern is a replica of the object to be cast, used to form the sand mould cavity into which molten metal is poured during the casting process. It is defined as a model of anything constructed in such a way that it may be used for forming an impression called “mould” in damp sand or other suitable material. Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. Web casting is a process in which we develop different shapes and sizes of things with the help of molds and patterns.

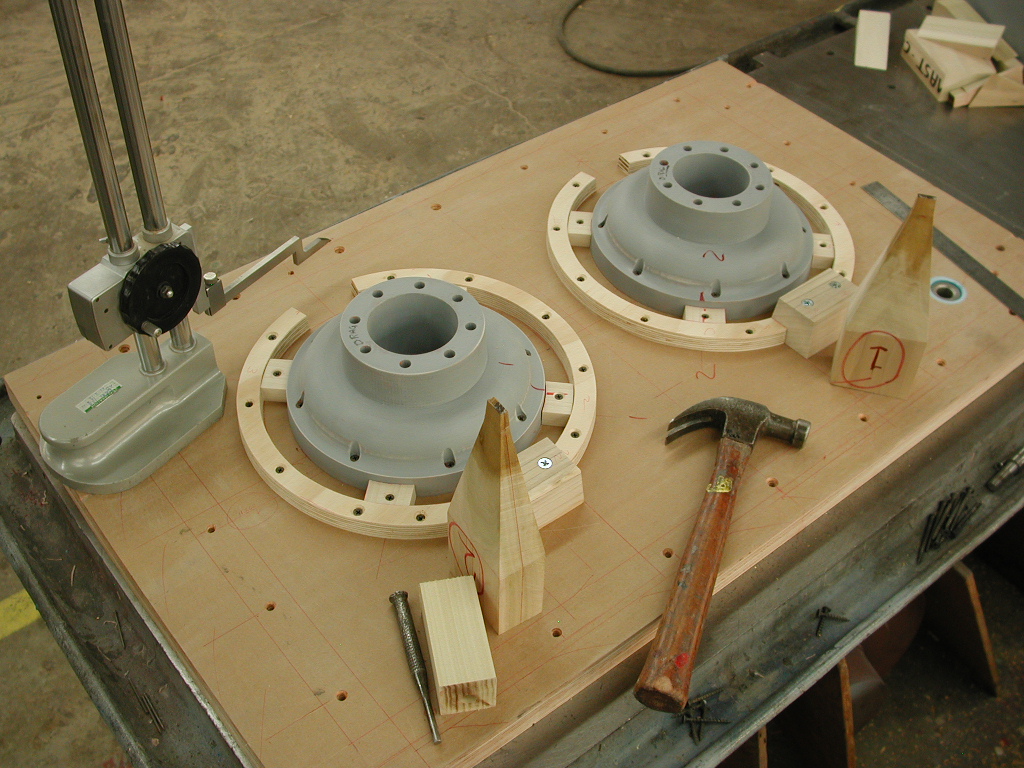

Patternmaking and Casting Pattern Making Patternmaking Castings

Web investment casting patterns often come in a single piece that resemble the final metal product closely—although runners might be built in for removal after.

Pattern Types and Mold Cavity Animation in Casting Process by Shubham

Patterns are a model for the object to be cast. Cores to accommodate holes can be seen in the bottom half of the mould, which.

Types of Pattern in Casting Process (Explained in Detail) PDF

The top half of the mould is called the cope. The no bake or air set process consists of packing sand mixed with a urethane.

11 Most Common Types of Patterns Used in Casting G For Games

The advantage of sweep pattern is that it reduces both expense and weight of pattern for. They can leave marks in many molds. Web 2.3.

Types of patterns used in Casting Process Mechanical Engineering

Supports a wide range of shapes and sizes. Web a pattern (or tool) is designed to optimize the castability of a part and provide a.

Steel Casting Patternmaking US Casting Company

In this type, the mold cavity is created by the complete sweep of the pattern. Sand casting is a typical example of a permanent pattern.

11 Most Common Types of Patterns Used in Casting G For Games

Web a wax pattern is used in the investment casting process. For example, a pattern for an aluminum part may be oversized by 5/32” per.

Casting Patterns and Patternmaking Metal Casting Blog

Sand casting is a typical example of a permanent pattern process, where a pattern is placed. So the pattern is very critical to the final.

Foundry Pattern Making Life of a Casting Reliance Foundry

Web a wax pattern is used in the investment casting process. Sand casting is a typical example of a permanent pattern process, where a pattern.

This Article Discusses The Types Of Patterns Used For A Specific Application Such As Loose Patterns, Match Plate Patterns, Cope And Drag Patterns, And Special Patterns.

It is used to create stuffing boxes for steam engines. Patterns are a model for the object to be cast. We use 10 different types of patterns in the casting process. There are different types of patterns in casting.

By Using This Pattern We Get A High Degree Of Accuracy And Can Have An Excellent Surface Finish.

It is defined as a model of anything constructed in such a way that it may be used for forming an impression called “mould” in damp sand or other suitable material. A replica pattern is used to create a mold out of rubber, metal, or resin. The shape is determined by the mold cavity, but something needs to shape the mold—that’s where the pattern comes in. The first casting patterns are known to be used probably 3500 years in mesopotamia with the help of beeswax.

Supports A Wide Range Of Shapes And Sizes.

As the deciding factor in a specific casting process, patterns play a vital role in determining quality and perfection. Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. Cores to accommodate holes can be seen in the bottom half of the mould, which is called the drag. There are more details about 10 different.

Increases Thermal And Abrasion Resistance.

For example, a pattern for an aluminum part may be oversized by 5/32” per foot whereas a bronze casting pattern may be oversized 3/16” per foot. In this type, the mold cavity is created by the complete sweep of the pattern. Evaporative pattern casting (epc) process is a sand molding process that makes use of evaporative patterns produced industrially by steam molding or machined out from a block of expandable polystyrene foam (eps) [1, 2].the pattern is buried in the sand mold and. The casting process can produce everything from art pieces to engine parts.