Metal Casting Patterns - (ap) — a swiss company will build a plant in georgia to make lightweight parts cast from metal for vehicles and energy generation. After the shell mold has completely cured, the cast. Web one of the prominent processes through which patterns are easily made pup of metals is casting. Once the sand is packed tight, the pattern can be removed and the cast will. The sand casting process involves using a furnace, metal, pattern, and sand mold. Patterns are a model for the object to be cast. Reasons for this are the various design considerations that affect whether the pattern creates a mold that will, in turn, create a product of acceptable. This optimization minimizes the defects and ensures consistent quality production of sound castings. Web casting is a process that creates solid metal shapes (castings) by filling voids in molds with liquid metal, and then letting the object cool. The pattern can be made from various materials, including wood, plastic, or metal, depending on the complexity of.

An Introduction to Metal Casting Process Stanford Advanced Materials

In casting, a mold is contained in a frame called a flask. (ap) — a swiss company will build a plant in georgia to make.

Metal Casting at Home Part 35 Pattern Making Start to Finish YouTube

Web making a pattern, also known as an object with a shape like the desired product, is the first step in the metal casting process..

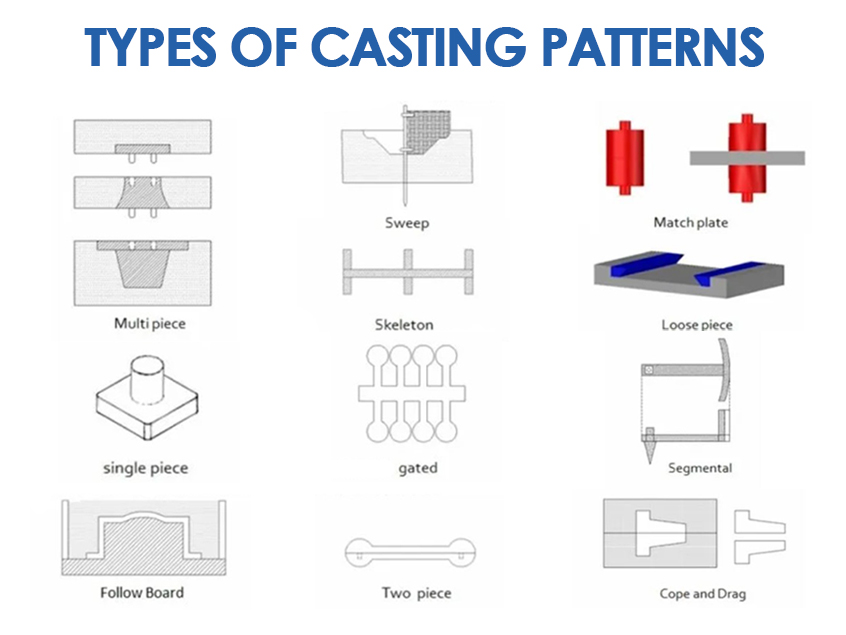

11 Most Common Types of Patterns Used in Casting G For Games

Web some of the basics you need to know if you are going to make a pattern to have cast in metal at a foundry.

Large Metal Casting Patterns Produced 33 Faster BigRep Industrial 3D

Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. (ap) — a swiss company will build a.

Types of Pattern in Casting Process (Explained in Detail) PDF

These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Cores to accommodate.

handverker sand casting using a 3d print as a pattern for casting in

Reasons for this are the various design considerations that affect whether the pattern creates a mold that will, in turn, create a product of acceptable..

Casting Patterns Functions, Material, Types, Allowances, Disadvantages

Reasons for this are the various design considerations that affect whether the pattern creates a mold that will, in turn, create a product of acceptable..

Casting Patterns and Patternmaking Metal Casting Blog

Web shell molding, also referred to as shell mold casting, is a precise casting process suitable for alloy steel and has six main steps. The.

Metal Casting With Single Sided Patterns.... Two Ways YouTube

The pattern, a production tool for the mold, needs to be slightly larger than the finished item. When completed, the mould cavity will be entirely.

Web Patternmaking Is The Initial And Critical Step In The Metal Casting Process.

A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. The process begins with the creation of a foam pattern, which serves as a replica of the desired metal part. This is to allow shrinkage during solidification. At arnette, we specialize in providing high quality, precision, wood, plastic, and metal foundry patterns for the metal casting industry.

Web Casting Is The Process Of Pouring Liquid Metal Into A Mold, Where It Cools And Solidifies.

These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. Web the casting pattern design of the gating and riser patterns plays a crucial role in achieving sound castings. Cnc machining is often used to create metal casting patterns.

Web Metal Casting Pattern:

This is known as metal sand casting. Both items are destroyed during the casting process (although the melted wax can often be reused). The sand casting process involves using a furnace, metal, pattern, and sand mold. Web casting is a process that creates solid metal shapes (castings) by filling voids in molds with liquid metal, and then letting the object cool.

Like Gravity Casting, Investment Casting Is Thousands Of Years Old.

Reasons for this are the various design considerations that affect whether the pattern creates a mold that will, in turn, create a product of acceptable. Web a thin mold is made around a heated metal pattern as part of the precision casting process known as shell molding. The shape is determined by the mold cavity, but something needs to shape the mold—that’s where the pattern comes in. Once the sand is packed tight, the pattern can be removed and the cast will.