Metal Casting Pattern - A core is a replica, (actually an inverse), of the internal features of the part to be cast. The process begins with the creation of a foam pattern, which serves as a replica of the desired metal part. It is designed for the mold which makes multiple components in one casting process. Cnc machining is often used to create metal casting patterns. Unlike a pattern, a core remains in the mold while the metal is being poured. The pattern, a production tool for the mold, needs to be slightly larger than the finished item. Most often, metallic patterns are used. The mold is made from a pattern, which is a replica of the final product. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. Web the casting pattern design of the gating and riser patterns plays a crucial role in achieving sound castings.

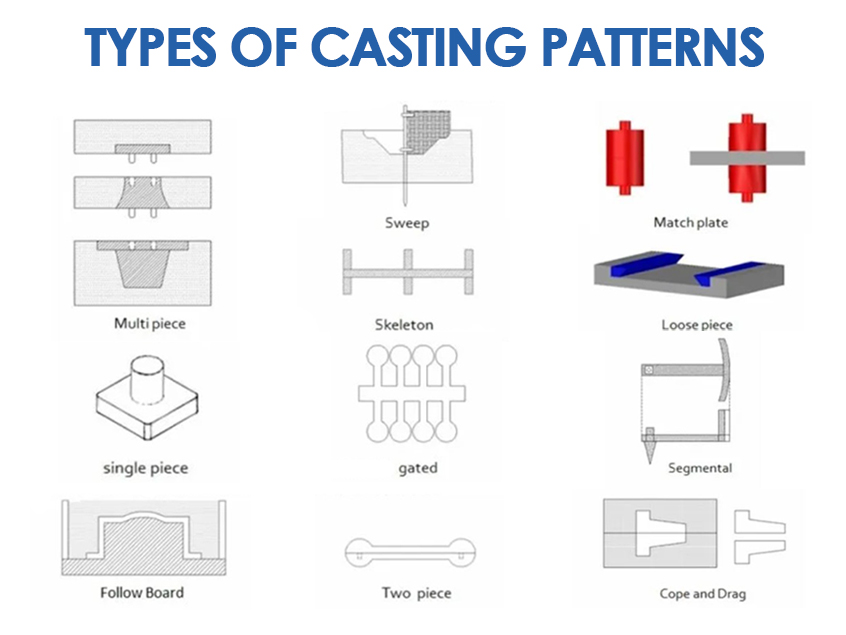

Types of Pattern in Casting Process (Explained in Detail) PDF

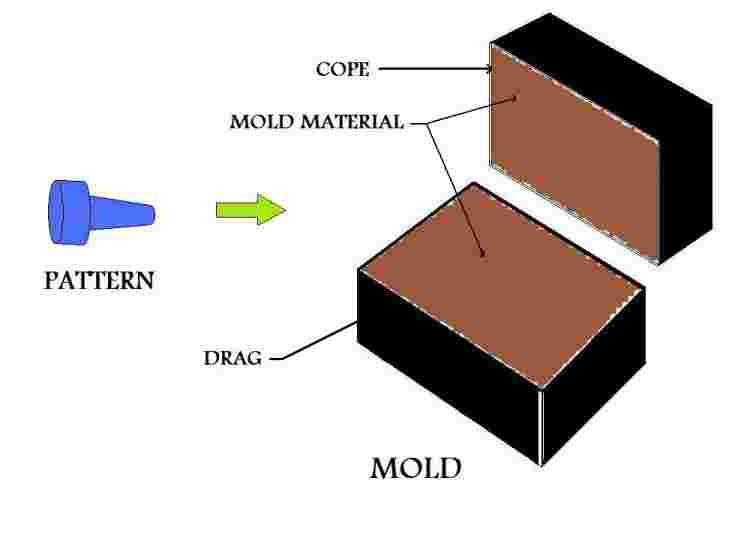

In metal casting, patterns are used to create the sand molds. This can be achieved using various methods, including cutting, molding, or 3d printing. It.

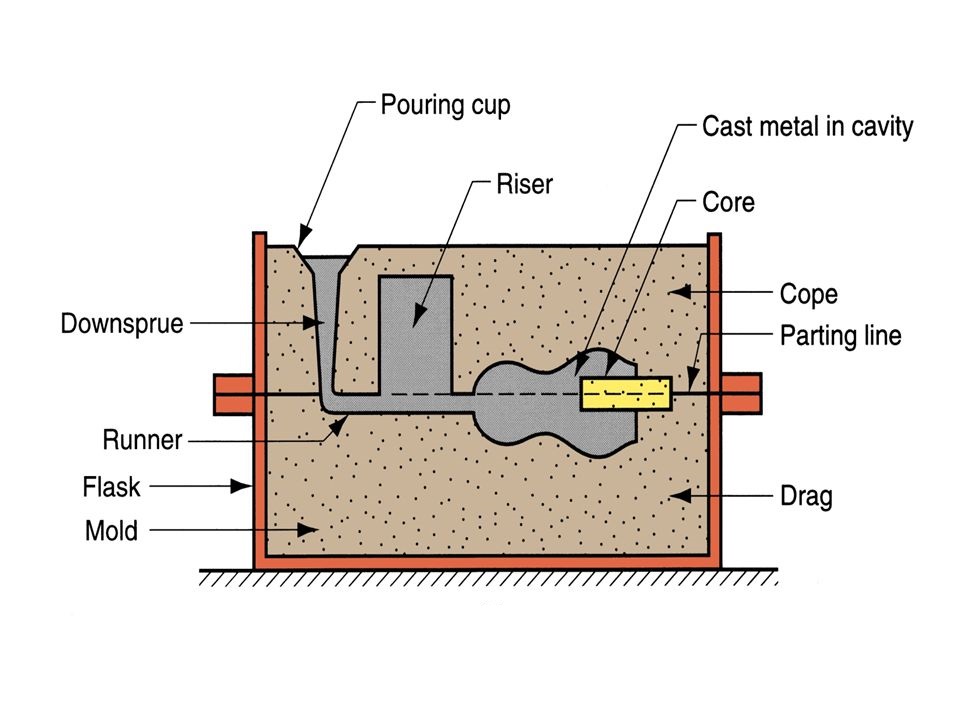

CASTING TERMINOLOGY Bajrang Engineering

The pattern engineer also has a responsibility of determining. Web the casting pattern designer has to observe the flow of steel into the mold to.

Casting Patterns and Patternmaking Metal Casting Blog

Pattern making is an art in itself, which requires a a lot of patience and hard work. Web for large castings, a special metal pattern.

Metal Casting Process

This can be achieved using various methods, including cutting, molding, or 3d printing. Accommodate the characteristics of the metal cast The gates are used to.

3D Printed Patterns For Metal Casting YouTube

The main functions of a pattern are to: Web metal casting pattern: Cores to accommodate holes can be seen in the bottom half of the.

Metal Casting Example Problem Casting Pattern design calculations

Carlos vasto, president of gf. Like a pattern, the size of the core is designed to accommodate for shrinkage during the metal casting operation. Cnc.

Casting Patterns Functions, Material, Types, Allowances, Disadvantages

The gates are used to combine the different patterns, and runners are. Carlos vasto, president of gf. Once the sand is packed tight, the pattern.

An Introduction to Metal Casting Process Stanford Advanced Materials

Difference between brazing and soldering [explained] #13 ceramic mold casting. Reasons for this are the various design considerations that affect whether the pattern creates a.

handverker sand casting using a 3d print as a pattern for casting in

To produce a quality casting, it is essential that the pattern is carefully designed, constructed, and finished. Web a replica pattern is used to create.

The Pattern, A Production Tool For The Mold, Needs To Be Slightly Larger Than The Finished Item.

This approach, which has roots in antiquity, offers simplicity and economics. The gates are used to combine the different patterns, and runners are. Cnc machining is often used to create metal casting patterns. In casting, a pattern is a replica of the object to be cast, used to form the sand mould.

The Shape Is Determined By The Mold Cavity, But Something Needs To Shape The Mold—That’s Where The Pattern Comes In.

Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Unlike a pattern, a core remains in the mold while the metal is being poured. Web making a pattern, also known as an object with a shape like the desired product, is the first step in the metal casting process.

The Metal Is Then Poured Directly Into The Mold, Which Vaporizes The Foam Upon Contact.

Carlos vasto, president of gf. Patterns are a model for the object to be cast. Most often, metallic patterns are used. Accommodate the characteristics of the metal cast

These Types Of Casting Process Creates Castings Using A Ceramic Slurry.

Ceramic mold casting ceramic mold casting is accomplished in much the same way as sand and plaster mold casting but uses a ceramic slurry to form the mold instead of sand or plaster. In casting, a mold is contained in a frame called a flask. It is designed for the mold which makes multiple components in one casting process. A pattern is a replica of the final product that will be cast, designed to include allowances for shrinkage of the metal during cooling and solidification.