Knurling Patterns - Web knurling is a machining process that creates a patterned texture on a workpiece's surface, improving grip and aesthetics. Talented creatorsunique & vintage itemseveryday supplies The knurling process enhances the part’s durability and aesthetics while improving its grip. Hand knurling is ideal for small workpieces and simpler patterns, while machine knurling is suitable for larger and more complex components. By using a tool with a specific pattern, manufacturing companies can achieve the same textured pattern on their products. A knurled pattern is frequently used on plastic mold casting to produce the impression of knurling in molded. Top brandsdaily dealsunder $10buy it now available It is done by using hardened metal wheels with special shapes to enhance the workpiece’s appearance and provide a better grip. Web unlock the secrets of knurling with our comprehensive guide! The purpose of knurling is to improve the grip or enhance the appearance of the object, making it easier to handle or manipulate by hand.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

A diamond pattern may also be created using a single diamond knurling wheel. A knurled pattern is frequently used on plastic mold casting to produce.

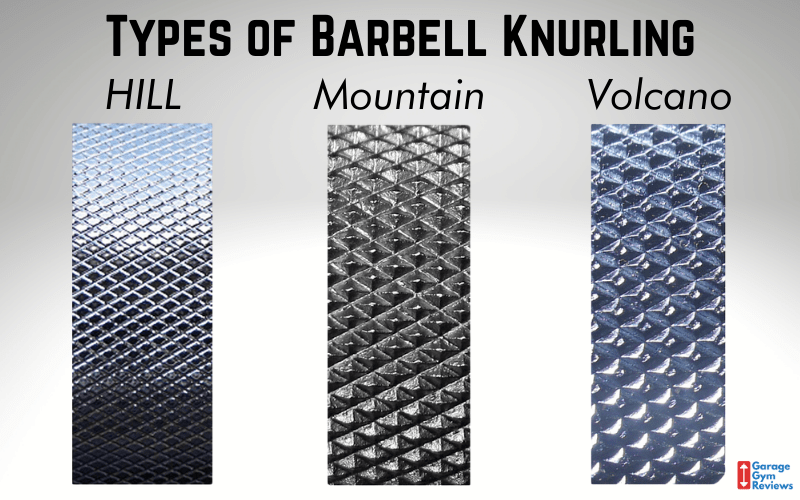

The 3 Types of Barbell Knurling and What It Means for Your Grip

Appeal, endurance, and traction than the initial smooth metal surface. Diamond shapes are another popular knurling pattern. Knurling serves to improve grip, facilitate. A female.

knurling operation? Purpose of knurling 5 knurl patterns knurling

Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto.

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS

Knurling is the process of creating a pattern on a workpiece to improve the visual appearance or to create a better grip on the part..

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

This technique, also known as cross knurling, involves using two wheels with matching diagonal patterns. It is done by using hardened metal wheels with special.

The 3 Types of Barbell Knurling and What It Means for Your Grip

Knurling uses the tool to displace material. Web the basics of knurling. Different patterns require various knurling. This textured pattern, called a knurl, provides enhanced.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

It can enhance the appearance of customized items by creating unique patterns such as ridges and swirls on milled surfaces. The patterns are created by.

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. A female diamond knurl.

Knurling.jpg (720×1200) Pattern design

Web unlock the secrets of knurling with our comprehensive guide! It makes diagonal knurls that slope to the left and right. For example, a micrometer.

A Great Example Of Knurling Is Seen On The Thimble Of Most Micrometers.

This pattern provides a secure grip in multiple directions, allowing for enhanced control and usability. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. It makes diagonal knurls that slope to the left and right. Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto a rotating workpiece.

The Knurling Process Enhances The Part’s Durability And Aesthetics While Improving Its Grip.

For example, a micrometer knob. Web knurling tools produce straight, diagonal, or diamond patterns, having teeth of uniform pitch on cylindrical surfaces. These patterns can consist of straight lines, angles, or interlocking designs. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface.

This Is Achieved By A Rotating Tool That Impressions The Desired Pattern Into The Metal.

Find tools, techniques, and strategies for producing perfect knurled finishes using jiahui custom’s services. There are two primary ways to perform knurling: Hand knurling is ideal for small workpieces and simpler patterns, while machine knurling is suitable for larger and more complex components. Creating either type of pattern is relatively easy, especially using a lathe.

Knurling Serves To Improve Grip, Facilitate.

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. This form of knurling is frequently used in areas where a strong grip is needed, like with wrenches, screwdrivers, or bike handles.