Knurling Pattern - When working with small diameters, a fine pitch is used. The indented patterns are designed to eliminate slippage. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Knurling is a popular way to finish handles of tools and other hardware, with a pattern of crossed lines rolled into metal to provide better grip and an. Take a look at how these machinists get their knurls done on a lathe. Three common knurl patterns are: This rough textured pattern enhances a part’s aesthetics and increases friction on its surface to facilitate grip. Web february 1, 2021 9:28 am. 4 essential steps for impeccable knurling results.

ADVANCETUTORIALS3DMODELS How to make knurling in SOLIDWORKS?

This rough textured pattern enhances a part’s aesthetics and increases friction on its surface to facilitate grip. These patterns can consist of straight lines, angles,.

knurling operation? Purpose of knurling 5 knurl patterns knurling

This is achieved by a rotating tool that impressions the desired pattern into the metal. The purpose of knurling is to improve the grip or.

Knurling.jpg (720×1200) Pattern design

Web february 1, 2021 9:28 am. The knurling process enhances the part’s durability and aesthetics while improving its grip. When working with large diameters, a.

How to Show Part Knurling in SOLIDWORKS Part 1

The knurling process enhances the part’s durability and aesthetics while improving its grip. Three common knurl patterns are: In some instances, knurling can also be.

How To Make Knurling Solidworks Tutorial YouTube

Web knurling patterns are produced in two types: Knurling is a popular way to finish handles of tools and other hardware, with a pattern of.

Knurled pattern on a flat surface — Onshape

7 using solidworks for knurling design and simulation. Knurl diamond pattern on the workpiece is equal to the width of the knurl wheel tool depth.

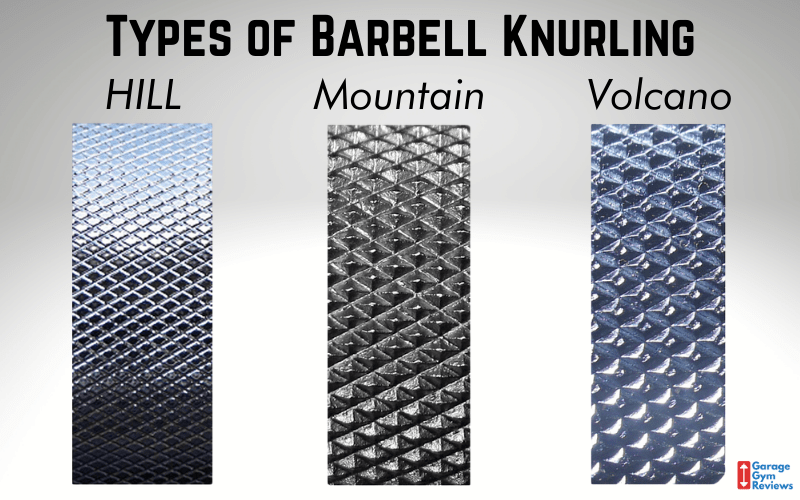

What is Barbell Knurling and Why It Matters Garage Gym Reviews

The knurling process enhances the part’s durability and aesthetics while improving its grip. Web knurling refers to a finishing process that makes patterns of concave.

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS

Knurling uses the tool to displace material. Web knurling is a process used to create a pattern on the surface of a material by displacing.

Why cut knurling patterns is the dinosaur of die casting

Web knurling comes in 4 main patterns: Knurling is a popular way to finish handles of tools and other hardware, with a pattern of crossed.

Unless Otherwise Specified Diamond And Diagonal Knurls Are Slanted 30°.

The grid pattern of the workpiece can vary. Knurling is a process that involves embossing a pattern onto a metal workpiece's surface. Knurling is often used on cylindrical parts like shafts, bolts, wheels, and tool handles. 4 essential steps for impeccable knurling results.

Web Knurling Comes In 4 Main Patterns:

Knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal, plastic, or wood. Web knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Knurling uses the tool to displace material.

The Indented Patterns Are Designed To Eliminate Slippage.

This article explains what is knurling, exploring the various types and common defects in knurling operations. Knurl diamond pattern on the workpiece is equal to the width of the knurl wheel tool depth with standard circular. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. This moving of the workpiece material creates the knurled pattern.

When Working With Large Diameters, A Coarse Pitch Is Used;

Materials that can be knurled. Straight or standard knurling pattern. The most common patterns include: Hand knurling is ideal for small workpieces and simpler patterns, while machine knurling is suitable for larger and more complex components.