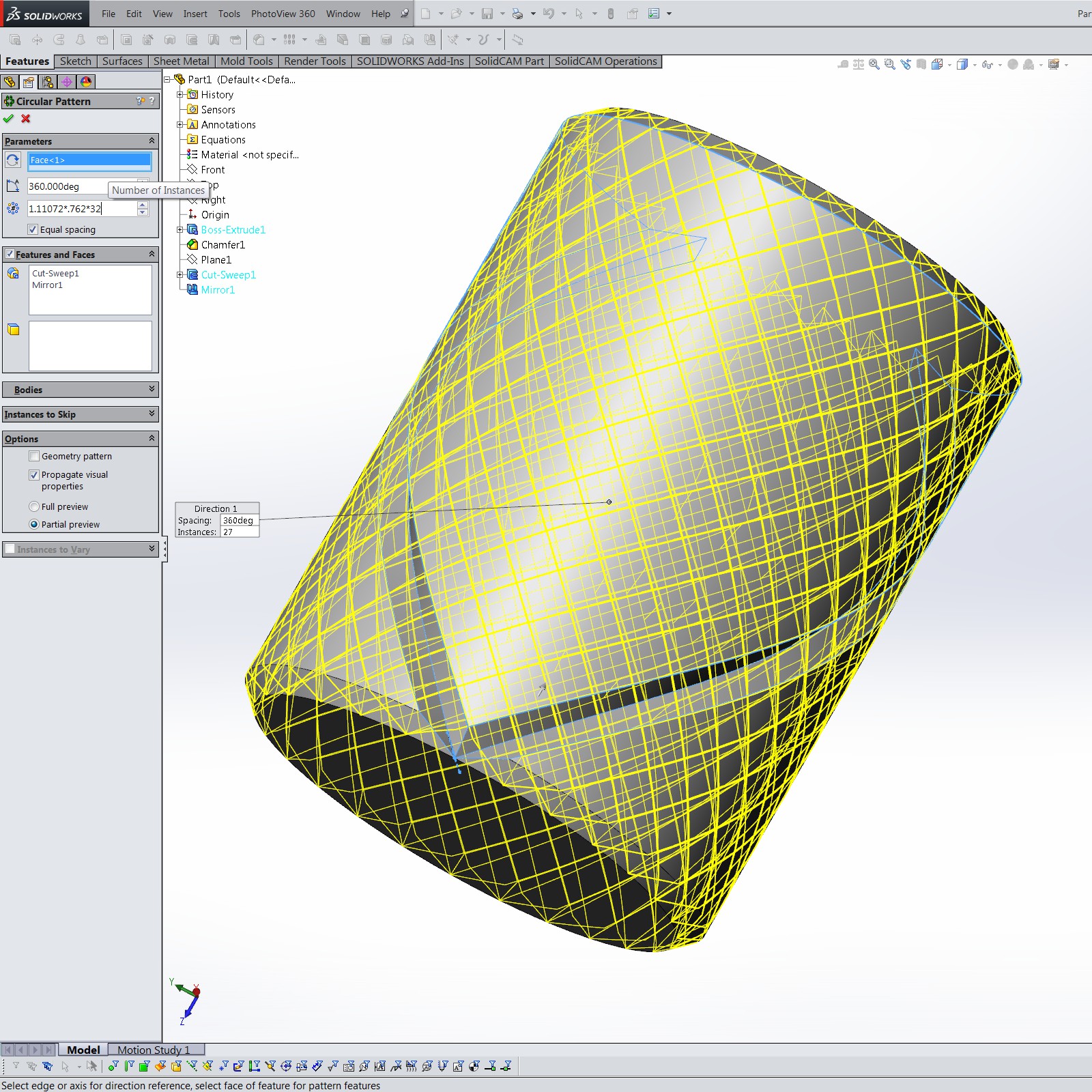

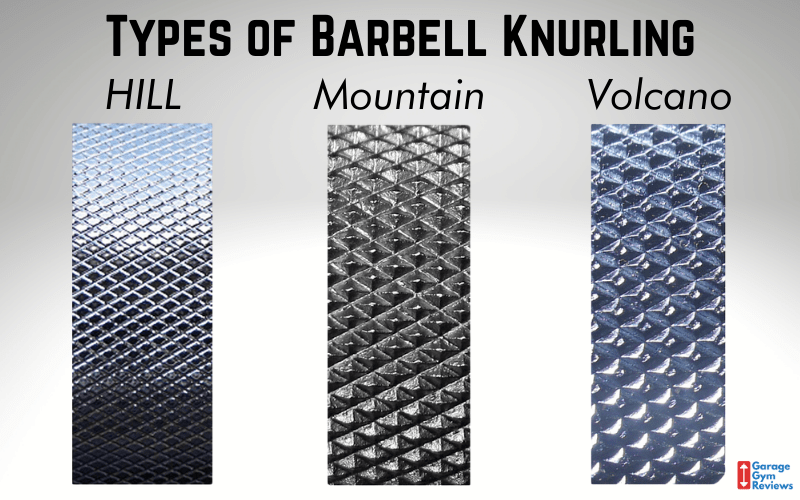

Knurl Patterns - These wheels are designed to apply pressure to the workpiece, causing the material to deform and create the knurled pattern. This is achieved by a rotating tool that impressions the desired pattern into the metal. The wheels are pressed against the workpiece simultaneously, creating a crisscross pattern. Left/right with tips raised, spiral angle: This technique produces a more aggressive texture than straight knurling, providing an even more secure grip. Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Different patterns require various knurling. A great example of knurling is seen on the thimble of most micrometers. The patterns are created by cutting or forming the surface material. Web knurling is a manufacturing operation, performed on a lathe, that copies a pattern from a knurling wheel onto a round workpiece.

Knurling.jpg (720×1200) Patterns & Textures Pinterest Patterns

A great example of knurling is seen on the thimble of most micrometers. Web knurling is a process used to create a pattern on the.

Accurate Knurls in SolidWorks Tom's Maker Site

Web knurl specification and tool size chart table. Once you’ve felt a knurl pattern you really like, any old bar won’t be good enough for.

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. The following table gives standardized.

Knurling designs

Knurling wheel sets are also. Diagonal, diamond and straight are the three most common patterns generated by knurling wheels. Knurl diamond pattern on the workpiece.

Knurling designs

The following table gives standardized diameter pitches and dimensional relationships when producing straight, diagonal, and diamond knurling on cylindrical surfaces having teeth of uniform pitch.

Knurl Patterns 1000 Free Patterns

Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Ansi standard knurls and knurling..

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

The knurling tool needs to be securely mounted in a tool holder. In general, knurling operations can act as a repair method. The standard knurling.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

Web there are two knurl patterns, diamond and straight. Ansi standard knurls and knurling. It is done by using hardened metal wheels with special shapes.

knurling operation? Purpose of knurling 5 knurl patterns knurling

Knurl diamond pattern on the workpiece is equal to the width of the knurl wheel tool depth with standard circular. Web knurling is a process.

Three Common Knurl Patterns Are:

The patterns are created by cutting or forming the surface material. Web knurling is a manufacturing operation, performed on a lathe, that copies a pattern from a knurling wheel onto a round workpiece. Web knurl specification and tool size chart table. Diagonal knurling is achieved by using two wheels with opposite diagonal patterns.

Knurling Is Done To Increase The Friction On A Surface, And Is Typically Performed On A Lathe To Cylindrical Parts.

The purpose of knurling is to improve the grip or enhance the appearance of the object, making it easier to handle or manipulate by hand. These wheels are designed to apply pressure to the workpiece, causing the material to deform and create the knurled pattern. Web knurling is a machining process that creates a patterned texture on a workpiece's surface, improving grip and aesthetics. The following table gives standardized diameter pitches and dimensional relationships when producing straight, diagonal, and diamond knurling on cylindrical surfaces having teeth of uniform pitch parallel to the cylinder axis or at a.

Web Barbell Knurling Is The Crosshatch Pattern On The Shaft Of Olympic Barbells That Is Intended To Increase Friction Between Your Hands And The Bar And Thus Improving Grip.

Web knurling is the process of creating a pattern on a workpiece to improve the visual appearance or to create a better grip on the part. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. It is done by using hardened metal wheels with special shapes to enhance the workpiece’s appearance and provide a better grip. Once you’ve felt a knurl pattern you really like, any old bar won’t be good enough for you anymore.

The Wheels Are Pressed Against The Workpiece Simultaneously, Creating A Crisscross Pattern.

This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. Knurling wheel sets are also. The standard knurling speed is set from 60 to 80 rpm, while the knurling feed is best from 0.04 mm. Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material.