Knurl Pattern - 20 feb, 2012 04:01 pm. It was initially used to improve the grip of tools and weapons. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Diagonal, diamond and straight are the three most common patterns generated by knurling wheels. Pair these knurls with a knurling tool to create patterns on a workpiece for an improved grip. Web knurling is a manufacturing process that is usually performed on a lathe and involves rolling a pattern of straight, angled, or crossed lines into the part’s surface. Knurling can also refer to material that has a knurled pattern. This is achieved by a rotating tool that impressions the desired pattern into the metal. The knurled part obtains added aesthetic appeal, increased durability, and better grip than the original smooth metal surface. So the pattern itself is fixed by the design of the tool head so you need to specify the tool type which gives you the pattern you want.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

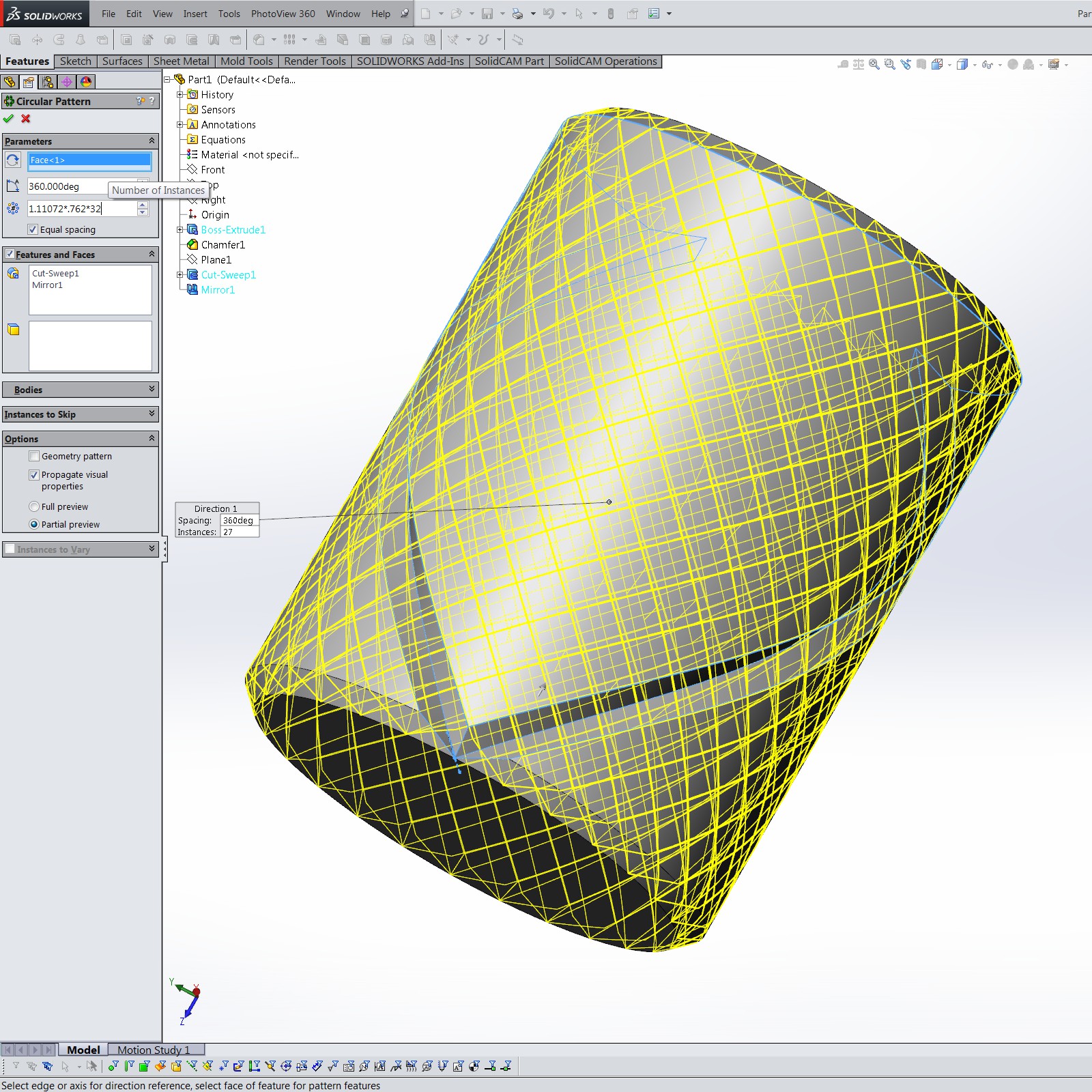

Draw a circle of 70mm diameter. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as.

Knurling.jpg (720×1200) Patterns & Textures Pinterest Patterns

It was initially used to improve the grip of tools and weapons. A brief history knurling has a rich history dating back to the early.

Titanium Wide Ring Textured Knurl Pattern Band Made to Any Sizing and

Web the two knurls should then be over and under the centerline of the workpiece. Web knurling comes in 4 main patterns: So the pattern.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. It is done.

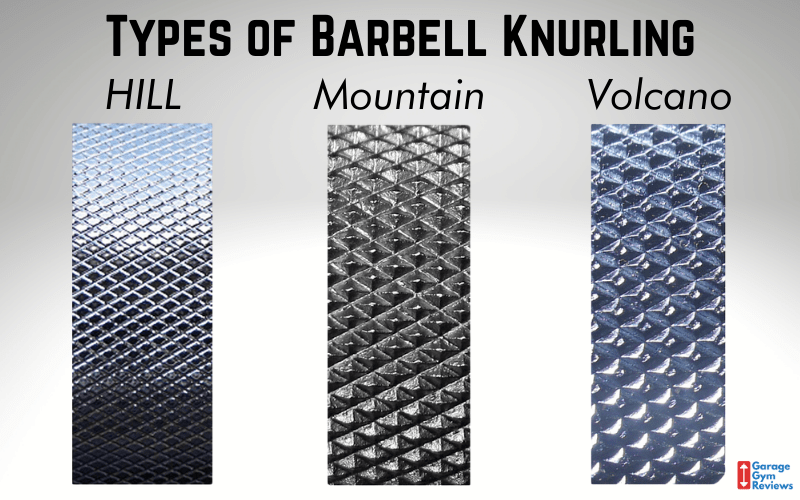

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Web master the art of knurling with our comprehensive guide. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

Web knurling is the process of creating a pattern on a workpiece to improve the visual appearance or to create a better grip on the.

Accurate Knurls in SolidWorks Tom's Maker Site

This is achieved by a rotating tool that impressions the desired pattern into the metal. Select both edge and chamfer it by 5mm at 45º..

The 3 Types of Barbell Knurling and What It Means for Your Grip

As a machinist or engineer, you may often encounter knurling in various applications, such as handles, knobs, and fasteners. So the pattern itself is fixed.

knurling operation? Purpose of knurling 5 knurl patterns knurling

Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. If you will also.

Knurling Is Done To Increase The Friction On A Surface, And Is Typically Performed On A Lathe To Cylindrical Parts.

Web it is a manufacturing process wherein a pattern is rolled onto a workpiece’s surface to improve grip, appearance, or functionality. It was initially used to improve the grip of tools and weapons. Pair these knurls with a knurling tool to create patterns on a workpiece for an improved grip. Different patterns require various knurling.

Unless Otherwise Specified Diamond And Diagonal Knurls Are Slanted 30°

It’s also affected by the finish that’s applied over the top. Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal, plastic, or wood. As a machinist or engineer, you may often encounter knurling in various applications, such as handles, knobs, and fasteners. This is achieved by a rotating tool that impressions the desired pattern into the metal.

Web Knurling Is A Finishing Process In Metalworking Where Grooves Or Patterns Are Formed On The Surface Of A Finished Part.

20 feb, 2012 04:01 pm. This moving of the workpiece material creates the knurled pattern. Web this textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. It is done by using hardened metal wheels with special shapes to enhance the workpiece’s appearance and provide a.

So The Pattern Itself Is Fixed By The Design Of The Tool Head So You Need To Specify The Tool Type Which Gives You The Pattern You Want.

Web knurling is a manufacturing process that is usually performed on a lathe and involves rolling a pattern of straight, angled, or crossed lines into the part’s surface. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Learn tools, techniques, patterns, and expert tips to elevate your knurling project today! The purpose of knurling is to improve the grip or enhance the appearance of the object, making it easier to handle or manipulate by hand.