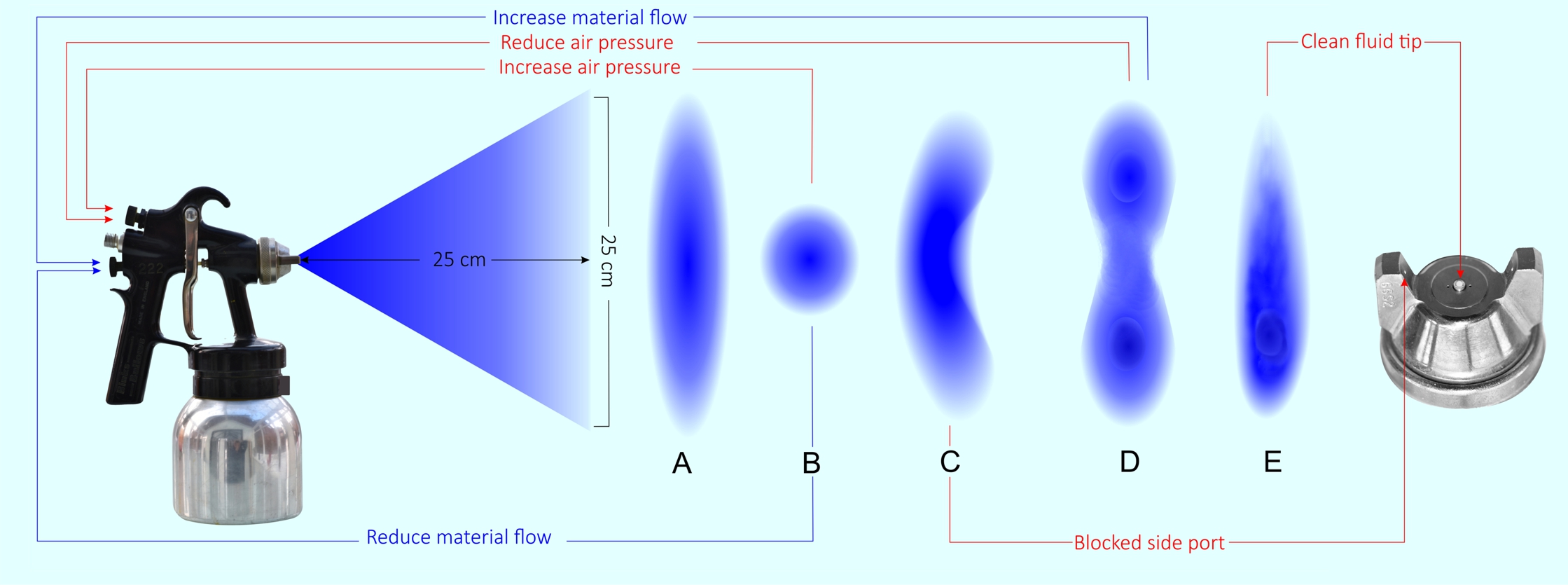

Graco Spray Pattern Troubleshooting - Web the pump can't pressurize if it's unable to cycle paint up into the pump. Move your arm while keeping the gun pointed straight at the surface being painted—don’t fan the. You could also switch to. Air in the pump or hoses is a result of an improperly primed pump. Web to troubleshoot spray pattern problems in a graco sprayer, you can check to make sure that the spray tip is clean and properly sized for the paint you are using. Operator is moving too slow speed of movement. This will cause a slight bulge in the diaphragm between the canister and the stainless steel casting. Web to address the issue, it is suggested to start with a pressure of around 75 bar and gradually increase it until you achieve a uniform spray pattern. Graco paint sprayer rtx1400si (2017) spray pattern has line top and bottom, tried two tips , changed. Spray pattern diagnostics troubleshooting spray pattern diagnostics problem cause solution spray pattern is pulsating:

6 Graco Airless Paint Sprayer Troubleshooting Tips To Know

Remove the spray gun, tip guard, and filter housing. Web poor finish or irregular spray pattern. Web matter can build up at the inside of.

Troubleshooting Guide For Graco Airless Paint Sprayers

If it is too low, it won't atomize properly and result in a splatter. Move your arm while keeping the gun pointed straight at the.

Troubleshooting Graco Airless Paint Sprayer How to Fix Common Problems

Web is your graco handheld sprayer spraying with poor results? Web here are the troubleshooting tips for clogs in the sprayer: Web to address the.

Graco Paint Sprayer Repair How to Replace the Gear and Yoke YouTube

Web matter can build up at the inside of the tip, partially plugging the tip and causing a bad spray pattern. Wear appropriate personal protective.

Graco Airless Spray Gun Spitting? How to Clean and Replace your Graco

Spray pattern diagnostics troubleshooting spray pattern diagnostics problem cause solution spray pattern is pulsating: Graco paint sprayer rtx1400si (2017) spray pattern has line top and.

Graco TruCoat 360 VSP Spray Pattern Problems Full Disassembly YouTube

Operator is moving too slow speed of movement. To avoid serious injury follow all warnings and instructions in the manual. Air in the pump or.

Graco Spray Tip Guide

Start by getting comfortable moving the spray gun and learning to maintain the recommended distance from the surface. Web is your graco handheld sprayer not.

Respraying a Setting up the compressor and spray gun Trouble

Over time, paint can build up inside the hose and clog the inside if you don't keep it clean. Depress the trigger to the first.

How to use a Graco paint sprayer Paint Sprayed

Test and confirm that the unit is working properly. If it is too low, it won't atomize properly and result in a splatter. Over time,.

The Air Supply Is Inadequate.

How to choose the right airless spray tip in 3 steps; To clear the blockage, you should remove the tip and clean it. Web poor finish or irregular spray pattern. To avoid serious injury follow all warnings and instructions in the manual.

Web The Blast Spray Pattern Is Sputtering Or Irregular To Avoid Serious Injury Follow All Warnings And Instructions In The Manual.

Web to address the issue, it is suggested to start with a pressure of around 75 bar and gradually increase it until you achieve a uniform spray pattern. Spray pattern diagnostics troubleshooting spray pattern diagnostics problem cause solution spray pattern is pulsating: Disassemble and clean the sprayer: Additionally, ensure that the pressure is set correctly and that the sprayer is properly primed.

Relieve The Pressure Applied In Step 2.

Remove the spray tip and guard, detach the suction tube, and clean all components with warm, soapy water or a suitable cleaning solution. Which filters and guard fit your airless spray tip? Priming will push out any air bubbles in the lines. Paint sprayer motor is stuck.

Web Paint Sprayer Pattern Problems:

Web an introduction to graco airless spray tips; Release pressure and remove paint: Start by getting comfortable moving the spray gun and learning to maintain the recommended distance from the surface. Air in the pump or hoses is a result of an improperly primed pump.