Diff Gear Patterns - The terms two cut and five cut refer to the machining process used to manufacture ring and pinion gear sets. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 (.10 mm) until correct pattern has been obtained. There are two types of gears which are determined by the machining method. This compound is used to show what the pattern actually is on the ring gear while adjusting the backlash. Ring gear and run a full contact pattern check. All dana drive axle models. Web every gear has a characteristic pattern. Observe all gear teeth for proper contact pattern and a uniform pattern from tooth to tooth. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 inch (.10 mm) until correct pattern has been obtained. I show you how i load up the gear set to both simulate the load of the vehicle and to give you.

Once backlash is within spec you can set the pinion depth by reading

In this video we give a quick demonstration of how to apply. A typical set of gears comes with a marking compound. Web one of.

How To Create & Read Ring Gear Patterns

Web every gear has a characteristic pattern. Use gear marking compound to paint all of the ring gear teeth. This is another relatively short read..

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting.

Differential Unitec automotive engineering study 2012

This is another relatively short read. Use shims to move the ring gear closer to the pinion to decrease backlash. All dana drive axle models..

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Use gear marking compound to paint all of the ring gear teeth. Observe all gear teeth for proper contact pattern and a uniform pattern from.

Ring Gear And Pinion Pattern

Use shims to move the ring gear closer to the pinion to decrease backlash. Dana drive axles require adjustment of the ring gear and pinion.

Can You Install Your Own Gears at Home?

Ring and pinion tooth contact pattern information p/n: The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web one of the.

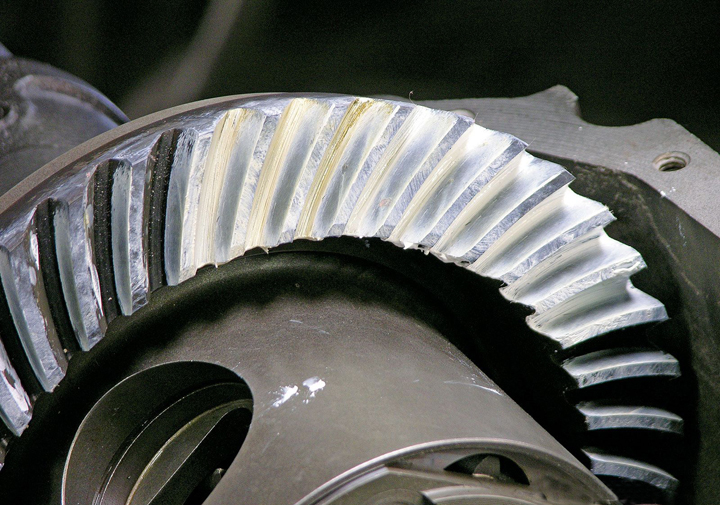

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. The order in.

How to Set up Your Rear Gear Correctly RacingJunk News

Observe all gear teeth for proper contact pattern and a uniform pattern from tooth to tooth. The terms two cut and five cut refer to.

The Illustrations Show Typical Patterns Only, And Explains How Patterns Shift As Gear Location Is Changed.

Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. One is manufactured by face hobbing, while the other one is manufactured by face milling. Differential installation instructions at differentials.com.

When Making Pinion Position Changes, Shims Should Be Changed In The Range Of.002 Inch (.05 Mm) To.004 (.10 Mm) Until Correct Pattern Has Been Obtained.

Find answers to the most asked questions about your purchase, order or shipping. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. I show you how i load up the gear set to both simulate the load of the vehicle and to give you. The only part of the pattern that helps me set pinion depth correctly is the contact position between the face and flank.

Pulling Off A Proper Differential Setup Comes Down To.

Web every gear has a characteristic pattern. Observe all gear teeth for proper contact pattern and a uniform pattern from tooth to tooth. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Dana drive axles require adjustment of the ring gear and pinion tooth contact at overhaul or anytime the axle has been disassembled.

The Order In Which Adjustments Are Made During Differential Assembly And Setup Are:

Ring and pinion tooth contact pattern information p/n: Web different backlash pattern markings—correct and incorrect. This is done using gear marking compound and checking the gear tooth pattern. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 inch (.10 mm) until correct pattern has been obtained.