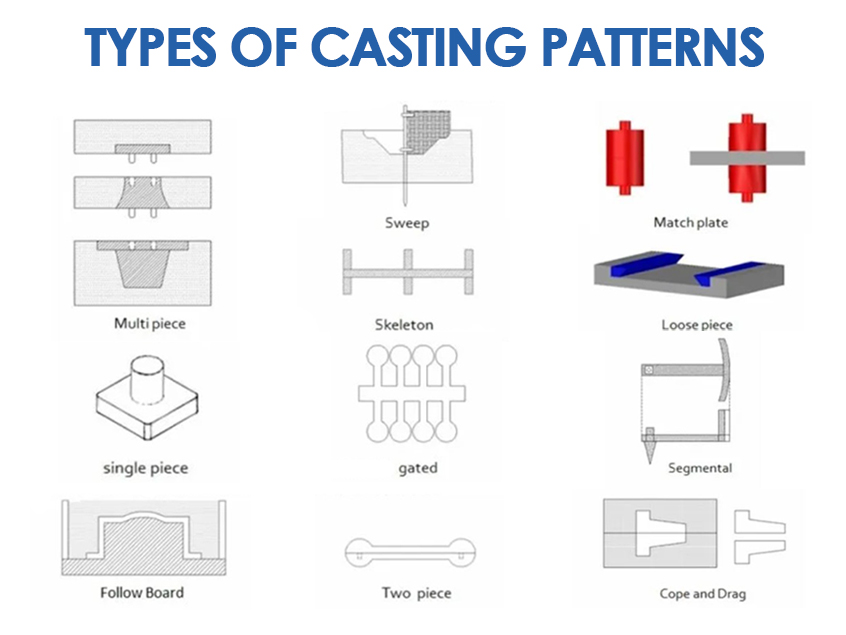

Casting Pattern - It is often known as just patterns. It is used to create stuffing boxes for steam engines. Web types of patterns in casting. After the investment material dries, the flask is placed upside down into a kiln, which melts the pattern. According to the shape and size of casting and method of making cavity, the pattern can be classified as follow: Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. A mold is a chamber into which molten metal is poured to form a desired shape, like the replica. Web casting patterns are the most crucial component in the metal casting process. The selection of material for casting pattern depends on different factors such as the number of casting, quality of casting and the degree of finish. Web a pattern (or tool) is designed to optimize the castability of a part and provide a casting that is dimensionally accurate.

Types of patterns used in Casting Process Mechanical Engineering

It describes the principles of the patternmaking techniques used to make expendable molds and for metal casting processes such as die casting and permanent mold.

Casting Patterns and Patternmaking Metal Casting Blog

It is used to create stuffing boxes for steam engines. Casting patterns for complicated casting. After the investment material dries, the flask is placed upside.

10 Different Typess of Pattern in Casting Engineering Choice

Patterns are produced in wood, plastic or polystyrene, depending upon customer needs. Web a pattern (or tool) is designed to optimize the castability of a.

11 Most Common Types of Patterns Used in Casting G For Games

Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. Web split patterns used for large casting and.

11 Most Common Types of Patterns Used in Casting G For Games

They are physical replicas or models used to create the mold. The selection of material for casting pattern depends on different factors such as the.

Patterns Clinch River Casting Iron Casting Foundry TN

Web casting patterns are the most crucial component in the metal casting process. Web investment casting patterns are typically made out of wax or 3d.

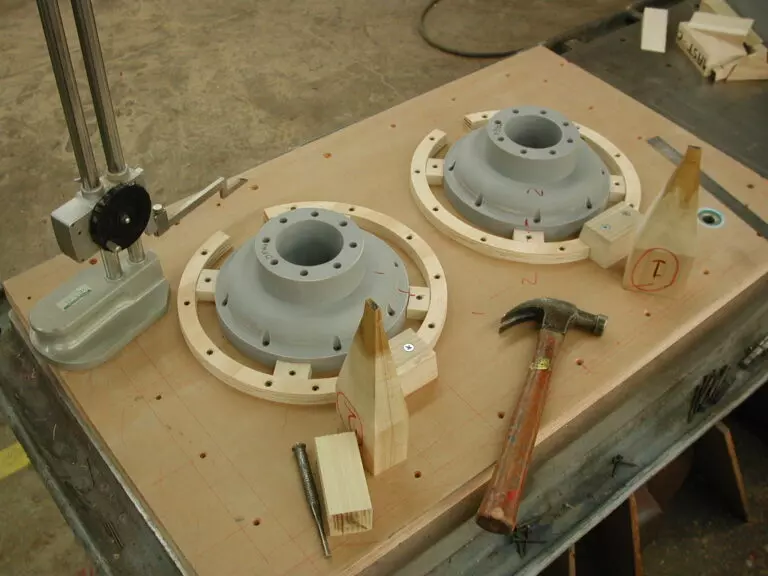

Foundry Pattern Making Life of a Casting Reliance Foundry

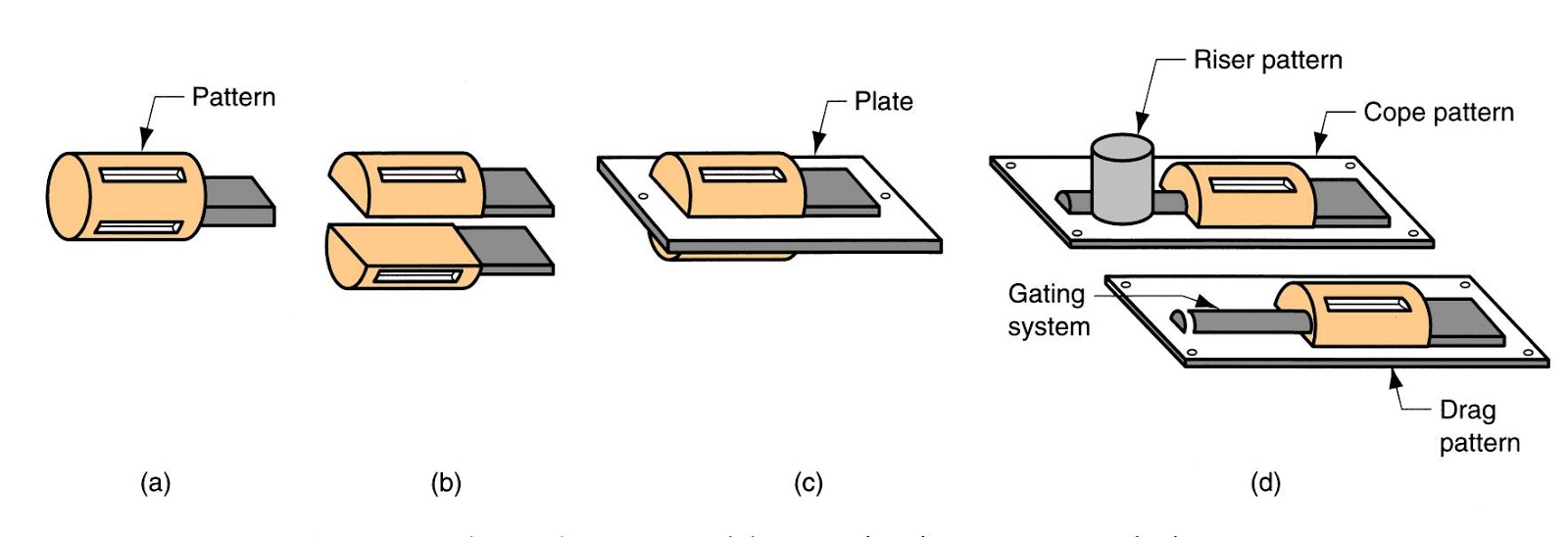

Mold pattern making in the foundry. In addition to split pattern, it has a gating and riser system attached separately to the face plates. The.

An Introduction to Metal Casting Process Stanford Advanced Materials

A split pattern is a type of pattern used in the casting process. Web patten is the tool used during the casting process. Web split.

Types of Patterns in Casting Process Mechanical Booster

Additionally “draft” needs to be added to any vertical surface on a. Every good ductile iron casting is the result of a good pattern. By.

In Casting, A Pattern Is A Replica Of The Object To Be Cast, Used To Form The Sand Mould.

A pattern can be both simple and complex for e.g an object that has detail on. A split pattern is a type of pattern used in the casting process. There are different types of patterns in casting. Single piece pattern, split pattern, gated pattern, multi piece pattern,

Web Types Of Patterns In Casting.

In addition to split pattern, it has a gating and riser system attached separately to the face plates. As we discussed, casting objects are highly dependent on the pattern. As the deciding factor in a specific casting process, patterns play a vital role in determining quality and perfection. Our use of polystyrene patterns for that “breakdown” one piece casting process, has many times put a customer back in operation in less than 2 weeks.

The Mold Will Allow For Mass Production Of The Original Pattern By Poring Some Sort Of Casting Material Such As Metal, Resin, Plaster, Or Other Material.

After the investment material dries, the flask is placed upside down into a kiln, which melts the pattern. One of the oldest living proofs of complex pattern in which a frog cast in copper has been found. It is often known as just patterns. It consists of two or more parts that can be separated to facilitate the removal of the pattern from the mold.

For Example, A Pattern For An Aluminum Part May Be Oversized By 5/32” Per Foot Whereas A Bronze Casting Pattern May Be Oversized 3/16” Per Foot.

The first casting patterns are known to be used probably 3500 years in mesopotamia with the help of beeswax. Mold pattern making in the foundry. Web a pattern (or tool) is designed to optimize the castability of a part and provide a casting that is dimensionally accurate. Web the main function of a casting pattern is to mold a cavity in the molding sand mixture such that the formed cavity looks the same as the casting product.