Carbon Fiber Patterns - Web raw carbon fiber from tows (or yarns) is woven together to make carbon fiber fabrics (or carbon fiber cloth). Web to prepare the modified carbon fiber/epoxy resin composites (cfrp), a vacuum molding technique was used in this study. Crev) is the parent of carbon revolution limited, an australian technology company, which has successfully innovated, commercialized and industrialized the advanced. The plate has a classic carbon fiber look. Web carbon revolution plc (nasdaq: Web lets first break down the different categories of carbon fiber woven fabrics. 5hs = 5 over 1. 120 carbon fiber micro check. Web this unique style of carbon fiber is simply a twill weave turned 90 degrees. Hydro dipped carbon fiber is preferred over actual carbon fiber because actual carbon fiber can add as much as 1/2 inch of material to the surface and pounds to the products weight.

30 Free Carbon Fiber Textures Patterns for Designers WebTopic

Because of its high fabric stability, plain. Web carbon revolution plc (nasdaq: These varying densities of carbon fiber will determine the strength and, therefore, the.

Carbon fiber texture seamless 21080

Imagine a thick plate of carbon fiber, roughly as thick as a ring's width (say 8mm), and comprised of up to 12 individual stacked woven.

Vector Seamless Carbon Fiber Pattern 226409 Vector Art at Vecteezy

Hydro dipped carbon fiber is preferred over actual carbon fiber because actual carbon fiber can add as much as 1/2 inch of material to the.

Carbon Fiber Pattern

Fill this rectangle with r=67 g=67 b=67 and place it exactly as shown in the first image. You can use these textures in any design.

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

Fill this rectangle with r=67 g=67 b=67 and place it exactly as shown in the first image. The carbon fiber manufacturing process begins with carbonization..

Carbon fiber texture seamless pattern Royalty Free Vector

The exposure to extreme heat that follows. Web to prepare the modified carbon fiber/epoxy resin composites (cfrp), a vacuum molding technique was used in this.

Carbon fiber seamless patterns Royalty Free Vector Image

Web carbon fiber patterns/weaves in this guideline we explain the difference between the pattern we offer our carbon fiber parts. As such, it’s a much.

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

3k has higher elongation to failure and a better strength than 6k, 9k or 12k. It’s light, relatively stiff, easy to find and simple to.

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

Web this unique style of carbon fiber is simply a twill weave turned 90 degrees. Web to prepare the modified carbon fiber/epoxy resin composites (cfrp),.

As Such, It’s A Much Tighter Knit And Much Harder To Warp.

Web this unique style of carbon fiber is simply a twill weave turned 90 degrees. Enjoy these hydro dipped carbon fiber patterns with out the bulk and weight. 3k is the workhorse of carbon fiber. To understand the x2 twill weave pattern, begin by examining its unique characteristics and applications.

As 3K Has A Smaller Bundle Of Fibers.

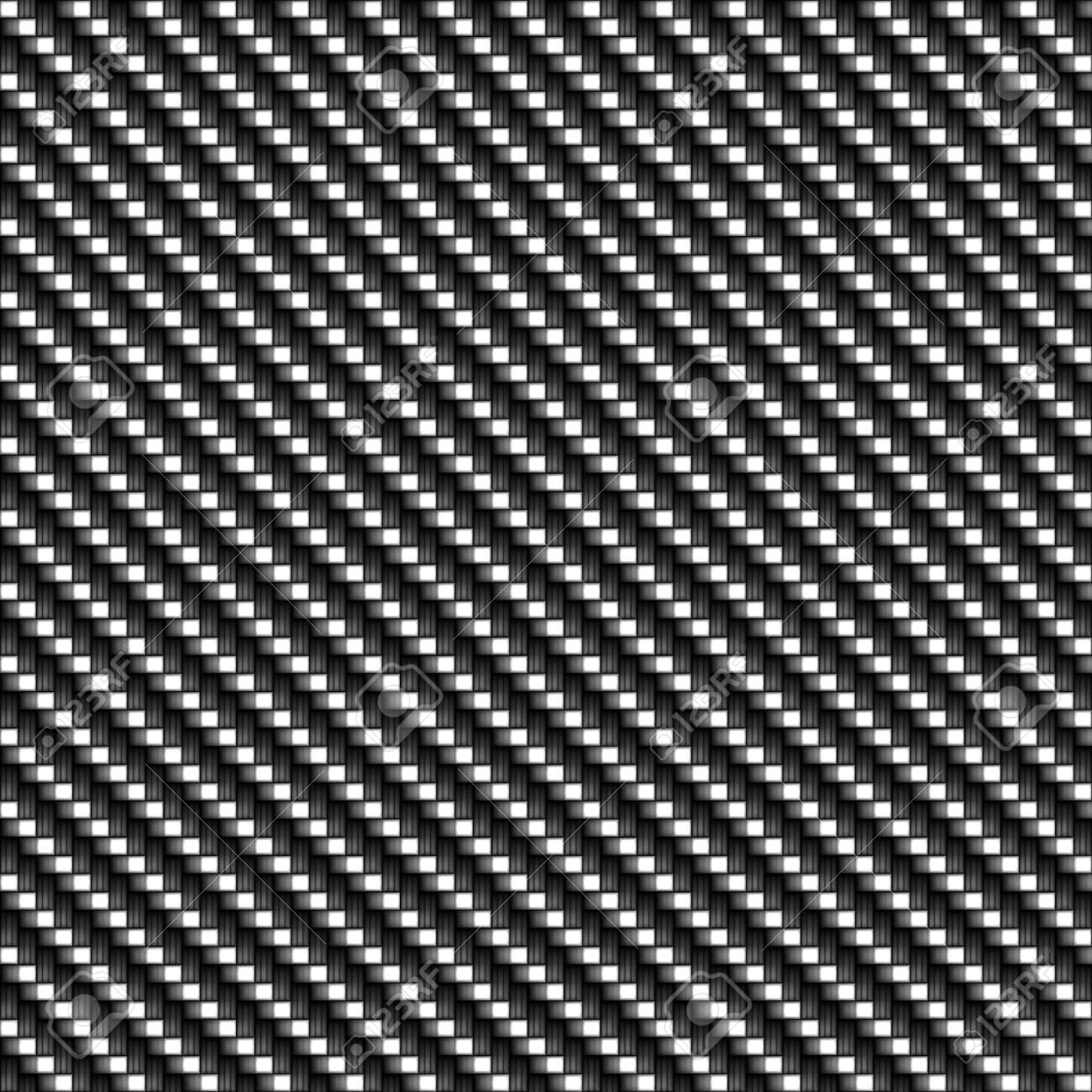

Web the second most used carbon fiber weave is the plain, or 1×1 weave. Imagine a thick plate of carbon fiber, roughly as thick as a ring's width (say 8mm), and comprised of up to 12 individual stacked woven carbon fiber layers. Crev) is the parent of carbon revolution limited, an australian technology company, which has successfully innovated, commercialized and industrialized the advanced. It is composed of fibers that are woven diagonally, creating a distinctive pattern that is known for its improved strength and performance compared to the plain weave pattern.

However, When Induced To Strong Forces,.

As the 2×2 name implies, each tow will pass over 2 tows then under two tows. 125 blue carbon fiber check. The three basic weave patterns are plain, twill, and satin. It looks more like a checkerboard due to the pattern of 1 tow going over another tow and under the next.

However, It’s Also Much More Difficult To Drape Over A Mold Than A Twill Weave.

Nevertheless, it should be handled carefully. 3k has higher elongation to failure and a better strength than 6k, 9k or 12k. 120 carbon fiber micro check. Web to prepare the modified carbon fiber/epoxy resin composites (cfrp), a vacuum molding technique was used in this study.