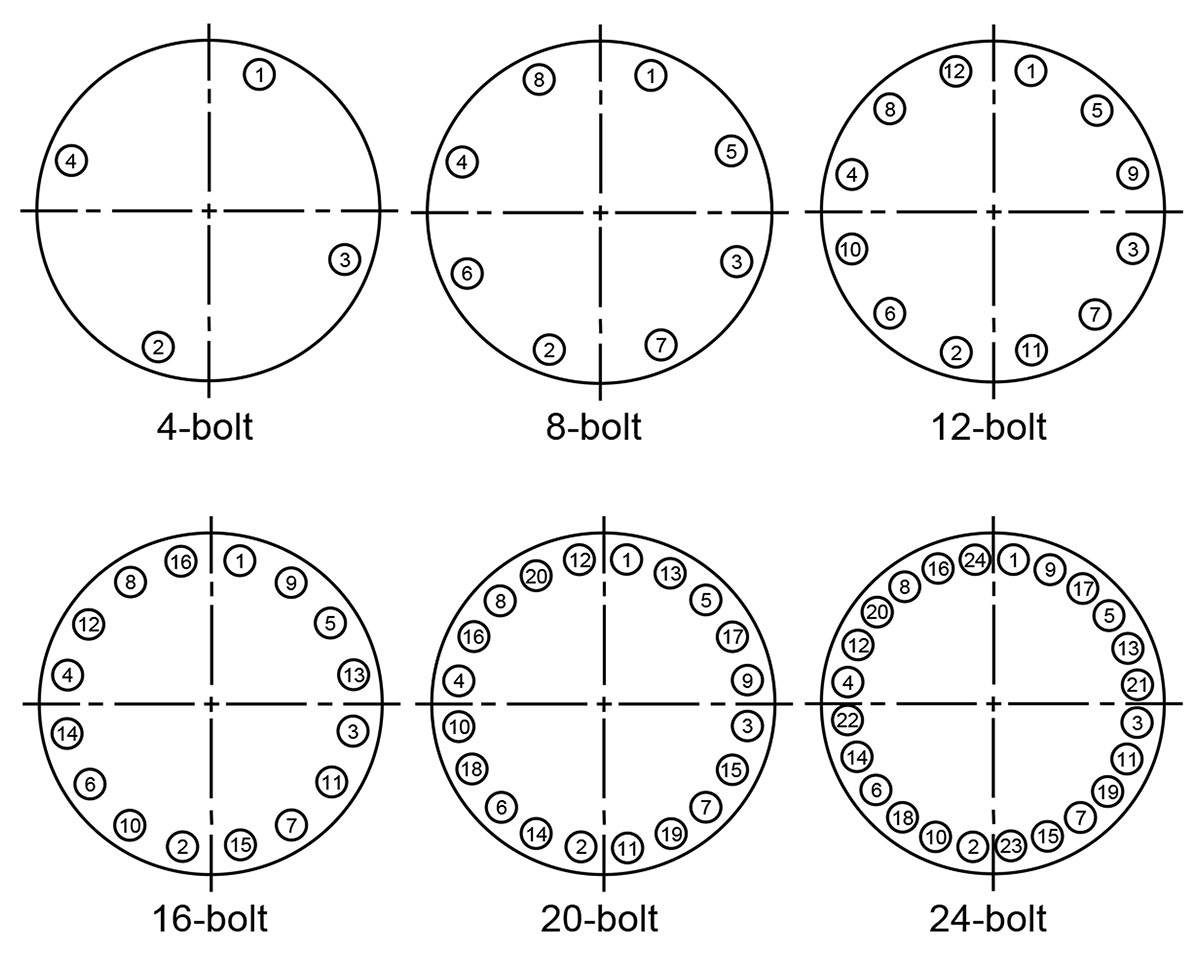

16 Bolt Flange Torque Pattern - 1 9 5 13 3 11 7 15 2 10 6 14 4 12 8 16. Applied torque, t= (k∙f∙d)/12 in fps unit. Web bolt torque is calculated for a flanged assembly using the following equation. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Table 8.1 minimum bolt pretension moved to table 5.2 in. In diameter and greater (table 3.1). The application of the recommended torque is only valid for the listed teadit products. The final tightening pass should be completed using the torque values specified in table 1. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. It’s also valid on all flange face and gasket types, including.

Torque Charts Industrial Torque Tools

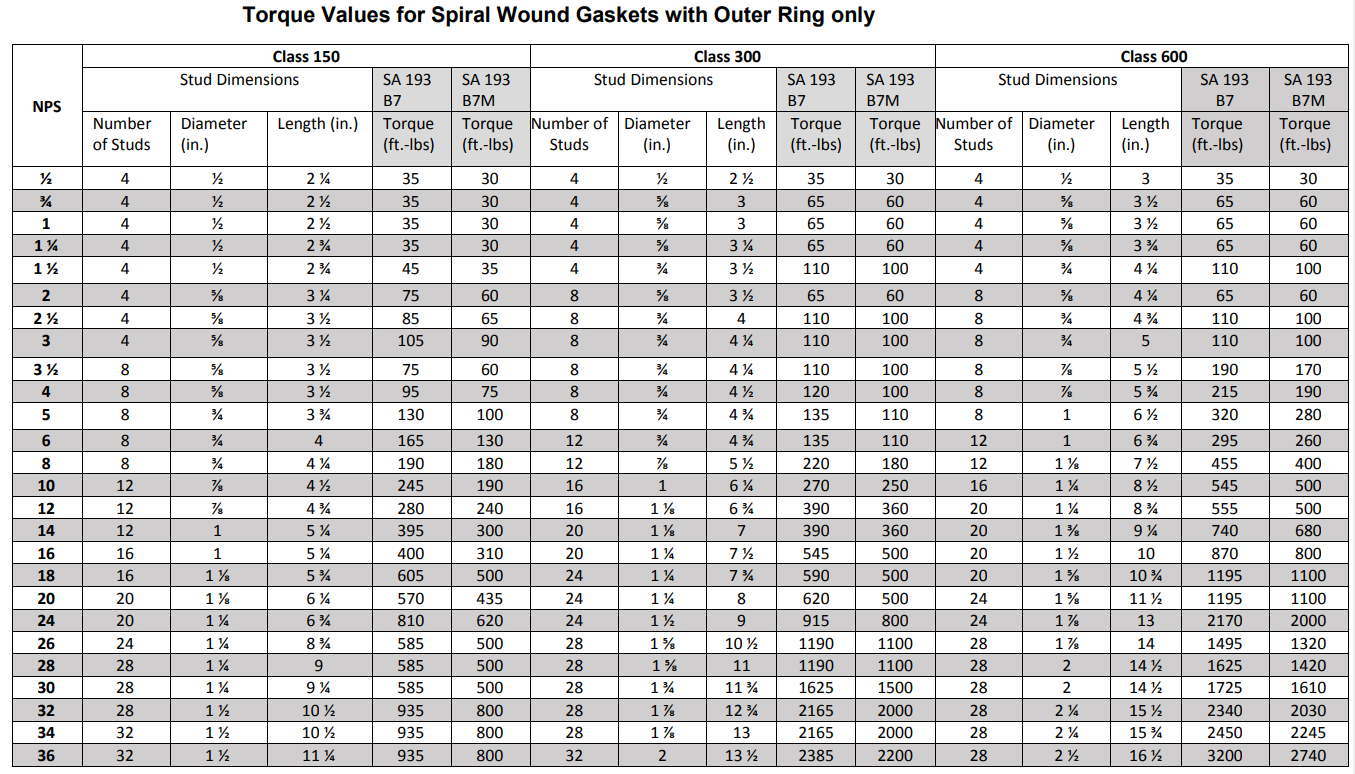

The final tightening pass should be completed using the torque values specified in table 1. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16.

16 Bolt Torque Pattern

Nominal pipe size (in) raised face. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. In diameter and greater (table.

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. Applied torque, t= (k∙f∙d)/12 in fps unit. The application of the.

Flange Bolt Torque Sequence Chart A Visual Reference of Charts Chart

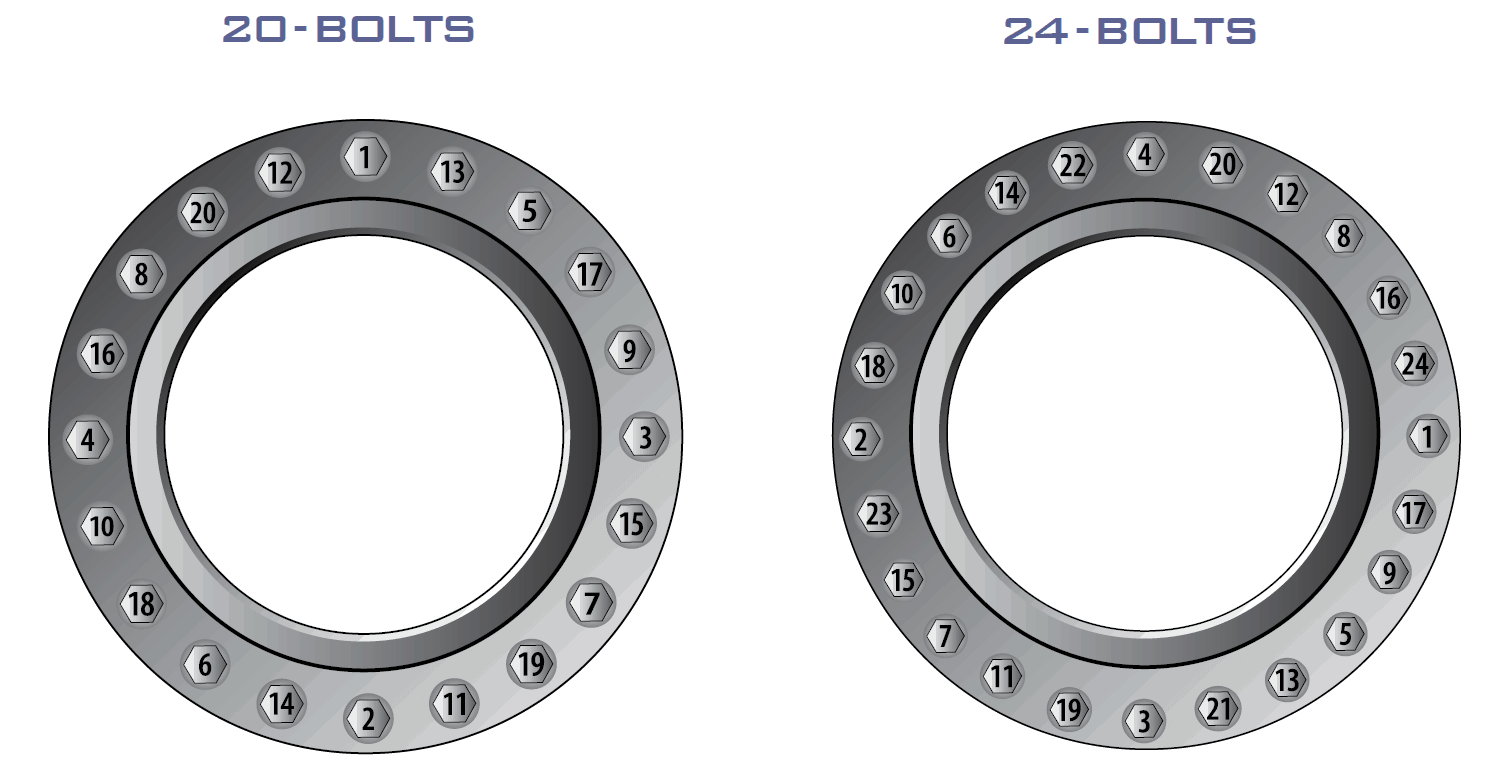

Web 16 bolt torque pattern. Ensure the inserts in the element are not. Lookup flange bolt torque patterns on your phone in seconds. Nominal pipe.

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

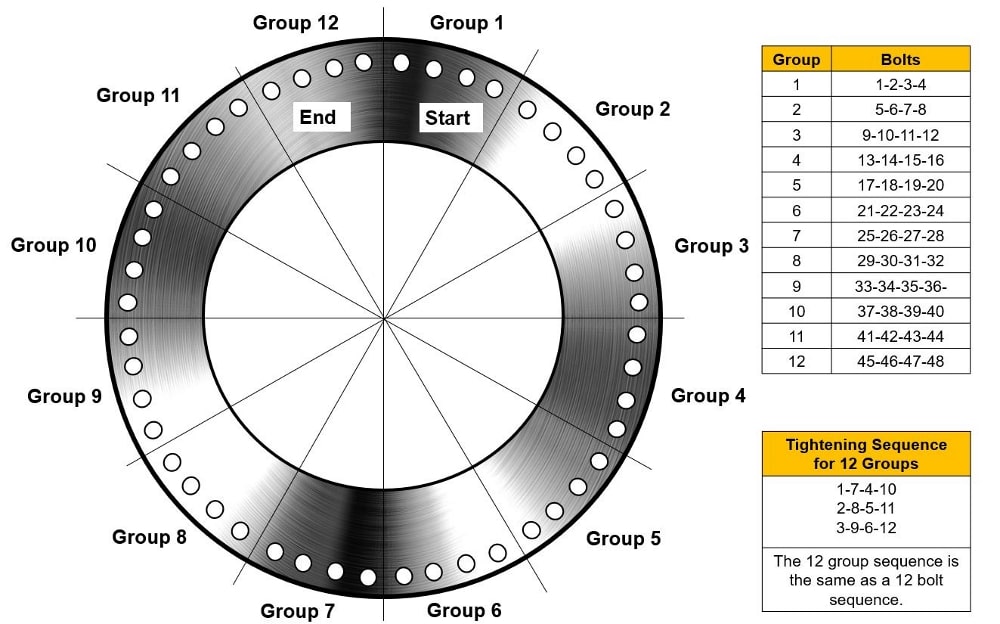

Ensure the inserts in the element are not. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web the.

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Web bolt torque is calculated for a flanged assembly using the following equation. Web the star bolting pattern is good for use on all asme.

FlangeBoltingPatterns Industrial Bolting and Torque Tools

Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Applied torque, t= (k∙f∙d)/12 in fps unit. Table 8.1 minimum bolt pretension moved to table 5.2 in..

Bolting Patterns Westorc

Web tighter each time around the pattern. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. East pompano beach, fl.

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Web torque bolt pattern sequence. Garlock sealing technologies an enpro industries company. Web 16 bolt torque pattern. Web bolt torque is calculated for a flanged.

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

The application of the recommended torque is only valid for the listed teadit products. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350.

The Application Of The Recommended Torque Is Only Valid For The Listed Teadit Products.

It’s also valid on all flange face and gasket types, including. East pompano beach, fl 33060. Table 8.1 minimum bolt pretension moved to table 5.2 in. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125.

Minimum Preferred Torque Torque (Ft.lbs.) (Ft.lbs.) Graphonic®.

Applied torque, t= (k∙f∙d)/12 in fps unit. The final tightening pass should be completed using the torque values specified in table 1. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. All tables in this brochure are only applicable under the following conditions:

Uip Supplies Gaskets Of All Types & Sizes For Many Industrial Applications.

Web bolt torque is calculated for a flanged assembly using the following equation. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. 1 9 5 13 3 11 7 15 2 10 6 14 4 12 8 16. Garlock sealing technologies an enpro industries company.

Web Flange Bolt Torque Sequence Www.hswhite.com | 954.785.6760 | [email protected] 1350 South Dixie Hwy.

Web torque bolt pattern sequence. Nominal pipe size (in) raised face. Web the star bolting pattern is good for use on all asme b16.5, b16.47, and heat exchanger flanges. Ensure the inserts in the element are not.